Phase Separation Technology

Let’s review some important aspects of the interesting phase separation technology:

The Role of Multiphase Separators

Multiphase Separator Terminology

The very first multiphase separator

The wide variety of separator designs

Phase Separation Zones

Operating Pressures and Capacities

Separator Internals

Common Operational Difficulties

CFD as a Separator Modeling Method

CFD Simulation of Multiphase Separators

The Role of Multiphase Separators

Multiphase

separators

are

one

of

the

most

prevalent

unit

operations

in

any

chemical

process.

Once

a

crude

oil

has

reached

the

surface,

the

main

purpose

of

the

surface

facilities

is

to

separate

the

produced

multiphase

stream

into

its

vapor

and

liquid

fractions.

Multiphase

separators

are

generally

the

first

process

equipment

in

an

oil

production

platform,

and

their

efficiency

influences

the

performance

of

all

downstream

equipment,

such

as

heaters,

compressors,

and

distillation

columns.

Thus,

oilfield

separators

play

a

key

role

in

the

production

capacity

of

entire

facility,

and

a

properly

sized

primary

multiphase

separator

can

increase

the

capacity

of

the

entire

facility.

In

some

oilfields,

water

(brine)

is

not

produced

together

with

oil,

and

hence

only

the

gas

and

the

oil

need

to

be

separated

(two-phase

separation).

However,

usually,

three-phase

separation

of

oil,

water,

and

gas

is

required

in

order

to

prepare

the

produced

multiphase

fluid

for

downstream

processing.

Multiphase Separator Terminology

Multiphase

separation

can

be

carried

out

through

various

oil

processing

equipment

with

the

specific

terminology

corresponding

to

each

system.

Hence,

it

is

worth

defining

the

most

important

multiphase

separators

in

the

oil

industry

before

proceeding.

The

conventional

oil

and

gas

separator,

which

is

normally

installed

on

a

production

facility

or

platform,

may

be

referred

to

as

“oil

and

gas

separator”,

“separator”,

“stage

separator”,

or

“trap”.

A

“knockout

vessel”

is

used

to

remove

either

water

or

all

liquid

from

the

well

fluid

flow.

An

“expansion

vessel”

is

the

first

stage

separator

vessel

usually

operated

at

a

low

temperature.

A

“flash

chamber”

or

“flash

vessel”

normally

refers

to

a

conventional

oil

and

gas

separator

operated

at

low

pressure

as

the

second

or

third

stage

of

the

multistage

separation.

A

“gas

scrubber”

is

an

oil

and

gas

separator

with

a

high

gas

to

liquid

ratio.

In

a

“wet-type

gas

scrubber”,

dust,

rust,

and

other

impurities

of

the

gas

phase

are

washed

using

a

bath

of

oil

or

other

liquid,

and

the

gas

flows

through

a

demister

to

further

remove

liquid

droplets

from

the

gas

stream.

A

“dry-type

gas

scrubber”

or

“gas

filter”

is

equipped

with

demisters

and

other

coalescing

media

to

aid

in

the

removal

of

most

of

the

liquid

from

a

gas

stream.

The very first multiphase separator

The

original

phase

separator

was

inclined,

very

long,

and

without

any

internal

separating

aids.

During

the

retention

time

(around

one

minute),

the

gas

and

oil

underwent

a

very

limited

separation.

Sir

Stephen

Gibson

designed

this

simple

phase

separator

and

also

the

multi-stage

separation

process.

He

was

the

first

to

put

this

process

into

operation

in

1930

at

the

Haft-Kel

oilfield in Iran (Skelton, 1977).

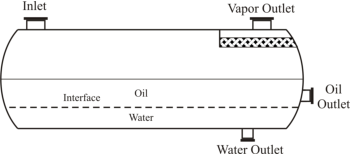

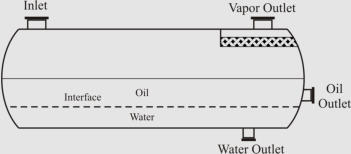

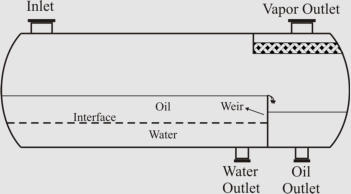

The wide variety of separator designs

A

wide

variety

of

separator

designs

and

configurations

for

multiphase

separators

in

both

vertical

and

horizontal

orientations

have

been

developed.

Various

parameters

such

as

space

and

operating

restrictions,

oilfield

variations,

potential

contaminants,

and

economic

evaluations

are

considered

in

the

design

of

a

multiphase

separation

system.

For

instance,

some

separators

may

be

equipped

with

special

impingement

internals

to

aid

the

separation

process.

The

figure

below

shows

some

different

common

designs

composed

of

“simple”,

“boot”,

“weir”,

and

“bucket

and

weir”.

These

designs

offer

a

variety

of

methods

to

control

the

interface

level

in

horizontal

three-phase

separators.

“Simple”

design

separator

can

easily

be

adjusted

to

handle

unexpected

changes

in

oil

or

water

density

or

flow

rates

(Arnold

and

Stewart,

2008).

A

boot,

typically,

is

used

when

the

water

fraction

is

not

substantial

(less

than

15-20%

of

total

liquid

by

weight),

and

a

weir

is

used

if

the

water

fraction

is

substantial

(Monnery

and

Svrcek,

1994).

The

bucket

and

weir

design

is

usually

used

when

interface

level

control

is

difficult

either

in

heavy

oil

applications

or

because

of

emulsions or paraffin problems (Arnold and Stewart, 2008).

(

a

)

(

b)

(

c) (

d)

Different Common Designs of Horizontal Three-Phase Separators; (a) “Simple”, (b) “Boot”, (c)

“Weir”, and (d) “Bucket and Weir”.

Phase Separation Zones

In

spite

of

the

variety

of

design

configurations

proposed

for

multiphase

separators,

the

phase

separation

process

is

accomplished

in

three

zones:

The

first

zone,

primary

separation,

uses

an

inlet

diverter

so

that

an

abrupt

change

in

flow

direction

and

velocity

causes

the

largest

liquid

droplets

to

impinge

on

the

diverter

and

then

drop

by

gravity.

In

this

zone,

the

bulk

of

the

liquid

phase

is

separated

from

the

gas

phase.

In

the

next

zone,

secondary

separation

zone,

gravity

separation

of

fine

droplets

occurs

as

the

vapor

and

liquid

phases

flow

through

the

main

section

of

the

separator

at

relatively

low

velocities

and

little

turbulence,

and

the

liquid

droplets

settle

out

of

the

gas

stream

due

to

gravity.

The

liquid

collection

section

in

the

bottom

half

of

separator

provides

the

retention

time

required

for

entrained

gas

bubbles

or

other

liquid

droplets

to

join

their

corresponding

phases

because

of

gravity

and

buoyancy.

This

section

also

provides

the

holdup

and

surge

volumes

for

safe

and

smooth

operation

of

the

separator.

Gas

flows

above

the

liquid

phase

while

entrained

small

liquid

droplets

are

again

separated

by

gravity.

The

final

zone,

coalescing

media,

is

designed

for

mist

elimination

in

which

very

fine

droplets

that

could

not

be

separated

in

the

gravity

settling

zone

are

separated

by

passing

the

gas

stream

through

a

mist

eliminator.

In

this

zone,

vanes,

wire

mesh

pad,

or

coalescing

plates

may

be

used

to

provide

an

impingement

surface

for

very

fine

droplets to coalesce and form larger droplets which can be separated out of gas stream by gravity.

Phase Separation Zones

Operating Pressures and Capacities

The

operating

pressure

of

separators

may

vary

from

a

high

vacuum

to

around

35

MPa

(Smith,

1987)

and

their

capacities

may

range

from

a

few

hundred

barrels

per

day

to

100000

barrels

per

day

or

more

(Skelton,

1977).

As

the

operating

pressure

of

a

separator

increases,

the

density

difference

between

the

liquid

and

gas

phases

decreases.

Therefore,

it

is

desirable

to

operate

multiphase

separators

at

as

low

a

pressure

as

is

consistent

with

other

process

conditions

and

requirements.

Most multiphase separators operate in a pressure range of 138 kPa to 10340 kPa (Smith, 1987).

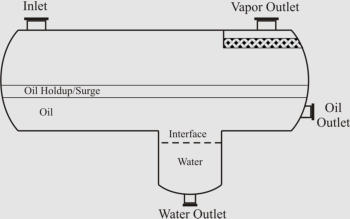

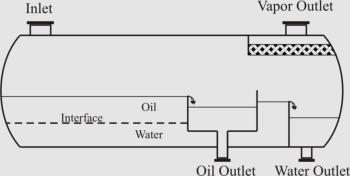

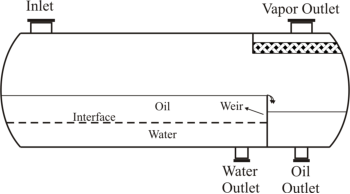

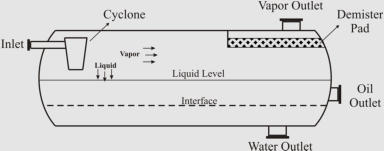

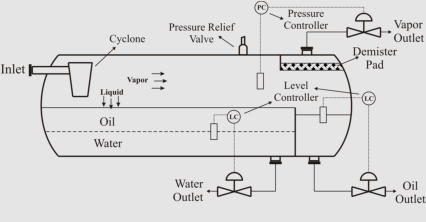

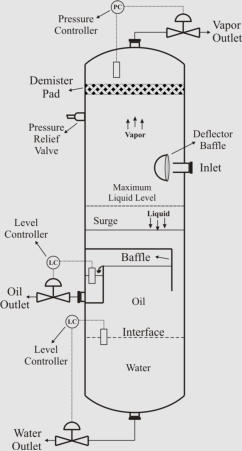

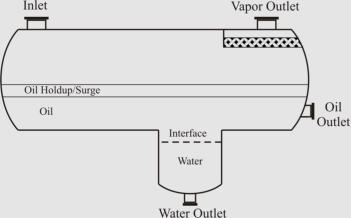

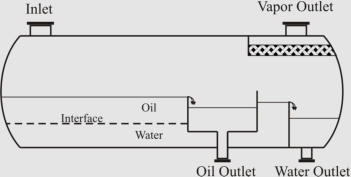

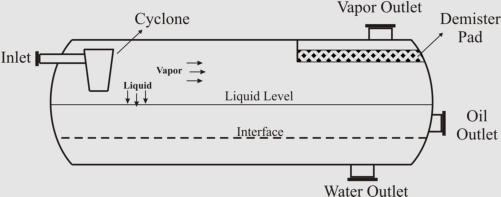

Separator Internals

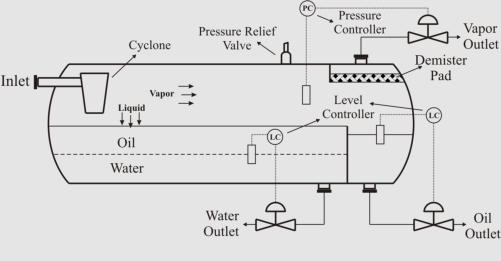

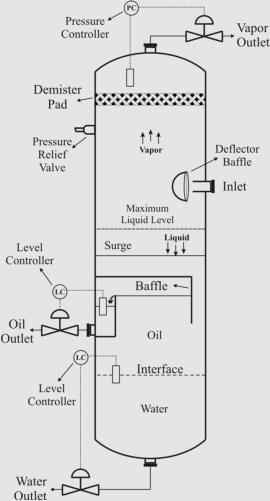

The

modern

separator

designs

have

much

higher

capacities

than

the

original

type

and

are

very

short

in

length

due

to

internals

such

as

inlet

diverters,

controls,

flow-distributing

baffles,

and

mist

extractors

which

enhance

the

separator

efficiency.

A

“weir”

design

horizontal

three-phase

separator

and

a

vertical

three-phase

separator,

both

with

the

installed

internals,

are

shown

in

the

Figures

below.

As

shown,

both

separators

are

equipped

with

inlet

diverters,

controls,

wire

mesh

demisters

and

pressure

relief

devices.

In

the

vertical

separator,

a

chimney

is

used

to

equalize

gas

pressure

between

the

lower

and

upper

sections

of

the

vessel.

Important

common

internals

are

explained as follows.

“Weir” Design Horizontal Three-Phase Separator with the Installed Internals.

Vertical Three-Phase Separator with the Installed Internals.

Inlet Diverters

Usually

a

deflector

baffle

or

a

cyclone

is

used

as

inlet

diverter

in

the

separator.

Deflector

baffles

come

in

various

shapes

and

can

be

installed

at

different

angles.

However,

hemisphere

or

conical

designs

are

preferred

because

they

cause

fewer

disturbances

than

plates

or

angle

iron

and

reduce

re-entrainment

and

emulsion

problems

(Arnold

and

Stewart,

2008).

Cyclone

diverters

are

increasingly

used

in

oil

production

facilities

as

they

promote

foam

breaking

and

mist

elimination

while

performing

the

bulk

gas-liquid

separation

in

the

inlet

zone

(Chin

et

al.,

2002).

Hence,

cyclone diverters can be used to increase the operating capacity of multiphase separators.

Controls

Separators

operate

at

a

predetermined

pressure

which

is

specified

by

economic

and

engineering

studies.

The

fixed

operating

pressure

in

a

separator

is

achieved

by

using

an

automatic

back

pressure

regulator

on

the

gas

outlet

line.

This

device

maintains

a

steady

operating

pressure

in

the

vessel.

The

liquid

level

controllers

and

liquid

outlet

control

valves

are

used

to

maintain

constant

oil

and

water

levels

in

the

separator.

Consequently,

the

operation

of

modern

separator

systems

is

completely automatic.

Mist Eliminators

Droplets

with

diameters

of

100

micron

and

larger

will

generally

settle

out

of

the

gas

stream

in

most

average-sized

separators.

However,

mist

eliminators

are

usually

required

to

remove

smaller

droplets

from

the

gas

phase

(Smith,

1987).

As

95%

of

droplets

entrained

in

the

gas

stream

can

be

separated

in

economically-sized

separators

without

coalescing

media,

the

efficiency

can

be

increased

to

around

100%

by

installing

mist

eliminators

(Walas,

1990;

Sinnott,

1997;

Arnold

and

Stewart,

2008).

These

coalescing

media

can

consist

of

a

series

of

vanes,

a

knitted

wire

mesh

pad,

or

cyclonic

passages

to

remove

the

very

fine

droplets

from

the

gas

phase

by

impingement

on

a

large

surface

area

where

they

collect

and

collide

with

adjacent

droplets.

The

mechanisms

used

in

various

mist

eliminators

are

gravity

separation,

impingement,

change

in

flow

direction

and

velocity,

centrifugal

force,

coalescence,

and

filtering

(Smith,

1987).

Mist

eliminators

can

be

of

many different designs exploiting one or more of these mechanisms.

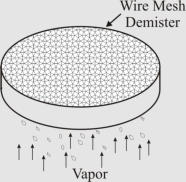

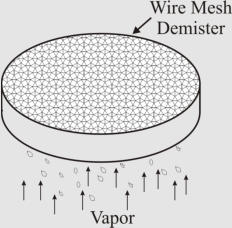

The

wire

mesh

pads,

shown

below,

are

made

of

knitted

wire

mesh

and

are

installed

by

a

lightweight

support

inside

separators.

Since

the

early

1950s,

the

wire

mesh

demisters

have

been

used

in

natural

gas

processing

with

the

main

use

of

removing

fine

droplets

ranging

from

10

to

100

micron

in

diameter

from

the

gas

stream

(Smith,

1987).

Generally,

high

separation

efficiencies

at

a

low

capital

and

maintenance

cost

are

experienced

from

using

standard

wire

mesh

demisters.

The

pressure

drop

is

a

function

of

the

entrainment

load,

the

mesh

pad

design,

and

gas

velocity

but

does

not

usually

exceed

295

Pa

(Lyons

and

Plisga,

2005).

Although

pad

thicknesses

up

to

0.9

m

have

been

used,

a

pad

thickness

of

0.10

m

to

0.15

m

is

normally

sufficient

for

most

separator

applications

(Gerunda,

1981;

Walas,

1990;

Lyons

and

Plisga,

2005).

However,

the

“fouling”

tendency

of

wire

mesh

demisters

may

restrict

their

applications

to

gas

scrubbers

(Smith,

1987).

In

fact,

knitted

wire

mesh

may

foul

or

plug

from

paraffin

deposition

and

other

impurities

and

thus

reduce

separation

efficiency

dramatically

after

a

short

period

of

service.

In

such

cases,

vane-type

or centrifugal demisters are used.

Wire Mesh Pad Mist Eliminator.

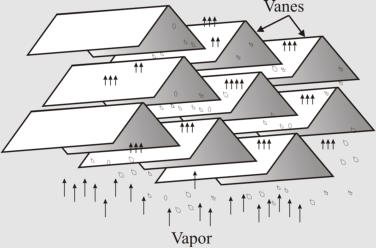

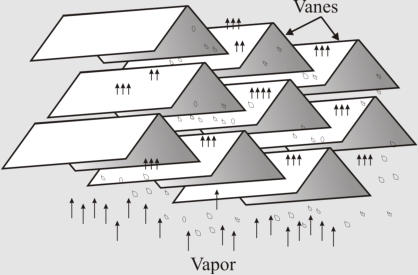

Vane-type

demisters,

shown

below,

are

widely

used

in

oil

and

gas

separators.

The

separation

mechanisms

used

in

most

of

vane-type

demisters

are

impingement,

change

in

flow

direction

and

velocity,

and

coalescence.

Vane-type

demisters

use

the

inertia

of

the

liquid

droplets

in

the

gas

stream

to

collect

a

film

of

liquid

on

the

vane

surface.

Vane-type

demisters

are

inexpensive

and

usually

will

not

plug

or

foul

with

paraffin

or

other

contaminants,

hence,

providing

a

good

separation

performance

under

widely

changing

field

conditions

(Smith,

1987).

Pressure

drop

across the vane-type demisters are very low, ranging from 250 Pa to 1 kPa (Smith, 1987).

Vane-Type Mist Eliminator.

Common Operational Difficulties

The

most

common

factors

which

can

reduce

separator

performance

are

very

high

or

very

low

liquid

level,

level

control

failure,

improper

design,

damaged

vessel

internals,

foam,

vortex

formation

in

liquid

outlet

zones,

plugged

liquid

outlets,

and

exceeding

the

design

capacity

of

the

vessel (Arnold and Stewart, 2008).

The

common

approaches

used

for

improving

the

separator

performance

in

difficult

cases,

as

proposed

by

Blezard

et

al.

(2000),

are

increasing

droplet

size

of

dispersed

phase

(e.g.,

by

promoting

coalescence),

inducing

a

high

acceleration

on

droplets

(e.g.,

by

using

centrifugal

force),

increasing

the

difference

between

fluid

densities

(e.g.,

by

introducing

diluents),

and

decreasing

the

viscosity

of

the

liquid

phases

(e.g.,

by

heating).

Some

of

these

approaches

may

be

combined

to

overcome

a

difficult

separation

task.

In

the

following,

some

different

measures

taken

for

operating

foamy,

emulsified, or contaminated crude oils are outlined.

Foamy

crude

oils

hinder

liquid

level

control

and

also

reduce

the

separation

space

of

the

separator.

To

improve

the

separator

performance,

it

is

usually

advantageous

to

inject

a

silicon

defoaming

agent

into

the

foamy

oil

stream

(around

1x10

-6

m

3

for

1

m

3

of

oil)

before

it

enters

the

separator

(Skelton,

1977).

This

agent

breaks

up

the

foam

and

keeps

oil

from

being

carried

over

by

the

gas

phase,

leading

to

an

effective

increase

in

the

capacity

of

the

separator.

The

other

approaches

that

assist

in

breaking

the

foam

are

settling,

baffling,

heat,

and

centrifugal

force

(Smith,

1987).

For

separators

suffering

from

liquid

carryover

while

processing

foamy

crude

oils,

or

glycols,

amines,

and

similar

materials

(with

high

foaming

tendency),

a

dual

mist

eliminator

system

composed

of

a

vane-type

demister

at

a

lower

level

and

a

wire

mesh

pad

at

higher

level

with

a

gap

of

0.15

to

0.30

m

between them is usually used (Lyons and Plisga, 2005).

The

other

separation

difficulty

is

caused

by

thoroughly

emulsified

oil.

The

water

phase

enters

the

bottom

of

the

producing

well

and

usually

breaks

up

into

fine

droplets

on

its

way

to

the

surface.

These

fine

droplets

form

an

emulsion

with

the

oil

phase

which

can

lead

to

a

fully

emulsified

phase.

Separation

of

the

thoroughly

emulsified

phase

is

extremely

difficult,

and

it

is

often

recommended

that

as

much

of

the

water

as

possible

be

removed

at

the

well

head

(Skelton,

1977).

This

treatment

is

done

by

processing

the

crude

oil

through

a

large

vessel

(long

retention

time)

which

would

allow

the

larger

water

droplets

to

settle

out.

If

further

treatment

of

the

separated

oil

phase

is

necessary,

the

oil

phase

may

be

heated

to

help

break

down

the

emulsion.

Usually,

a

surface

tension

reducing

chemical

is

also

added

to

enhance

the

treatment.

Generally

the

combined

application

of

heat

and

chemicals

is

sufficient

to

reduce

the

water

and,

consequently,

the

salt

content

of

the

oil

phase

to

an

acceptable

level

(Skelton,

1977).

However,

sometimes

the

use

of

an

electrical

coalescing

media

may

be

necessary

to

achieve

specification

level

of

oil

product.

In

this

treatment

method,

the

oil-water

stream

is

exposed

to

an

electrical

field

which

agitates

the

water

droplets

and

causes

them

to

collide

and

coalesce

into

larger

droplets

and

then

to

settle

out

of

the

oil

phase.

The

resultant

water

concentration

in

the

effluent

oil

stream

is

usually

less

than

0.5%

(Blezard et al., 2000).

Another

emulsion

problem

is

experienced

when

some

very

fine

particles

cause

a

stabilized

rag

layer

at

the

oil-water

interface.

In

order

for

the

separator

to

operate

properly,

the

rag

layer

must

be

regularly

broken

or

removed.

For

this

purpose,

some

techniques

such

as

filtration,

heating,

and

chemical injection are used (Hooper, 1997).

Contaminated

crude

oils

are

also

difficult

to

process.

The

most

common

contaminants

are

sand,

silt,

mud,

and

salt.

Medium-sized

sands

in

small

quantities

can

be

removed

by

an

oversized

vertical

settler.

The

residue

should

be

removed

periodically

by

draining

from

the

vessel

bottom.

Salt

may

be

removed

by

washing

the

oil

with

water

and

then

separating

the

salty

water

from

the

oil phase.

CFD as a Separator Modeling Method

Computational

Fluid

Dynamics

(CFD)

is

inherently

connected

with

the

“fluid”

concept.

It

is

interesting

that

this

“fluid”

concept

can

still

be

defined

as

Isaac

Newton

proposed

more

than

300

years

ago

in

the

following

elegant

way:

“A

fluid

is

any

body

whose

parts

yield

to

any

force

impressed

on

it,

and

by

yielding,

are

easily

moved

among

themselves.”

The

physical

features

of

any

fluid

flow

are

governed

by

three

fundamental

physical

principles:

mass

is

conserved,

Newton’s

second

law

applies,

and

energy

is

conserved.

These

fundamental

physical

principles

can

be

represented

in

terms

of

mathematical

equations,

generally

in

the

form

of

integral

equations

or

partial

differential

equations.

Computational

fluid

dynamics

is

the

art

of

replacing

the

integrals

or

the

partial

derivatives

in

these

equations

with

their

equivalent

discretized

algebraic

forms.

These

discretized

algebraic

equations

are

then

solved

to

provide

numbers

for

the

flow

field

values

at

discrete

points

in

time

and/or

space.

Therefore,

in

contrast

with

an

analytical

solution,

the

final

product

of

a

CFD

modeling

is

a

collection

of

numbers.

CFD

solutions

generally

require

the

iterative

manipulation

of

many

thousands,

even

millions,

of

numbers.

This

task

is

obviously

impossible

without

the

aid

of

a

high-speed

digital

computer

which

accelerated

the

practical

development

of

CFD.

The

historical

development

of

CFD,

as

reviewed

by

Anderson

(1995),

indicates

that

before

1970,

there

was

no

CFD

in

the

way

that

we

think

of

it

today,

and

although

there

was

CFD

in

1970,

the

storage

and

speed

capacity

of

computers

limited

all

practical

solutions

essentially

to

two-dimensional

flow

problems.

However,

by

1990,

this

story

had

changed

dramatically.

In

today’s

CFD

modeling

applications,

three-dimensional

flow

field

solutions

are

abundant

and

such

solutions

are

becoming

more

and

more

prevalent

within

industry

and

government

facilities.

Indeed,

some

computer

programs

for

the

calculation

of

three-dimensional

flows

have

become

industry

standards,

resulting

in

their

use

as

a

tool

in

the

design

process.

In

short,

CFD,

along

with

its

role

as

a

research

tool,

is

playing

an

increasingly

stronger

role

as

a

design tool.

The

high

storage

capacities

and

calculation

speed

of

present

computers

and

advanced

techniques

devised

in

modern

CFD

solvers

have

culminated

in

today’s

common

use

of

commercial

software

packages

for

CFD

simulation

of

industrial

equipment.

Currently,

CFD

software

packages

are

routinely

used

to

modify

the

design

and

to

improve

the

operation

of

most

types

of

chemical

process

equipment,

combustion

systems,

flow

measurement

and

control

systems,

material

handling

equipment,

and

pollution

control

systems

(Shelley,

2007).

For

implementation

of

a

CFD

simulation

using

a

commercial

software

package,

the

geometry

of

the

object

of

interest

is

specified

(with

a

computer

aided

design

drawing

of

the

object)

and

the

corresponding

discretized

grid

system

is

created

using

a

mesh-generation

tool.

For

mesh

generation,

present

software

tools

provide

some

predefined

building

units

in

a

variety

of

forms

such

as

tetrahedral,

pyramidal,

hexahedral,

and

recently,

polyhedral

blocks.

However,

generating

a

high

quality

mesh

for

the

system

is

still

one

of

the

most

technical

and

time-consuming

phases

in

any

CFD

based

analysis.

After

preparing

the

grid

system,

the

initial

and

boundary

conditions

of

the

problem

are

specified,

and

the

CFD

parameters

are

set.

Finally,

the

CFD

software

proceeds

with

the

iterative

process

of

solving

the

fundamental

equations

for

fluid

flow.

As

noted,

once

a

converged

solution

is

achieved,

CFD

simulation

output

is

a

collection

of

numbers

which

correspond

to

the

defined

points

in

space

or

time.

In

order

to

visualize

these

CFD

simulation

results

and

obtain

qualitative

aspects

of

the

system, the post-processing tool of CFD software is used.

CFD

complements

the

approaches

of

pure

theory

and

pure

experiment

in

the

analysis

and

solution

of

fluid

dynamic

problems.

Although

CFD

will

probably

never

completely

replace

either

of

these

approaches,

it

helps

to

interpret

and

understand

the

results

of

theory

and

experiment.

It

should

be

noted

that

suitable

problems

for

CFD

often

involve

predictions

outside

the

scope

of

published

data,

where

experimental

studies

are

too

expensive

or

difficult

or

where

the

development

of

an

insight

is

required

(Sharratt,

1990).

Therefore,

CFD

is

primarily

an

insight

tool

which

is

useful

for

understanding

the

important

features

of

a

system

and

for

elucidating

and

solving

some

system

uncertainties and problems.

CFD Simulation of Multiphase Separators

In

our

recent

research

project,

we

applied

Computational

Fluid

Dynamics

(CFD)

based

simulation

to

model

multiphase

separators.

In

order

to

capture

both

macroscopic

and

microscopic

aspects

of

multiphase

separation

phenomenon,

an

efficient

combination

of

two

multiphase

models

was

used.

The

Volume

of

Fluid

(VOF)

model

was

used

to

simulate

the

phase

behavior

and

fluid

flow

patterns,

and

the

Discrete

Phase

Model

(DPM)

was

used

to

model

the

movement

of

fluid

droplets

injected

at

the

separator

inlet.

The

“particle

tracking”

based

simulation

of

the

multiphase

separation

process

was

the

key

aspect

of

this

research

project,

and

the

developed

model

did

provide high-quality visualization of multiphase separation process.

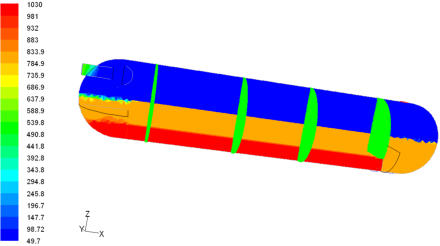

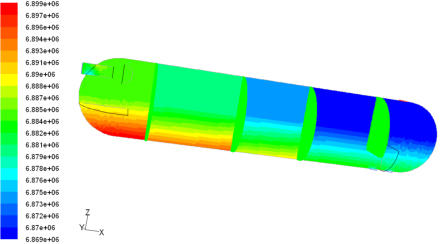

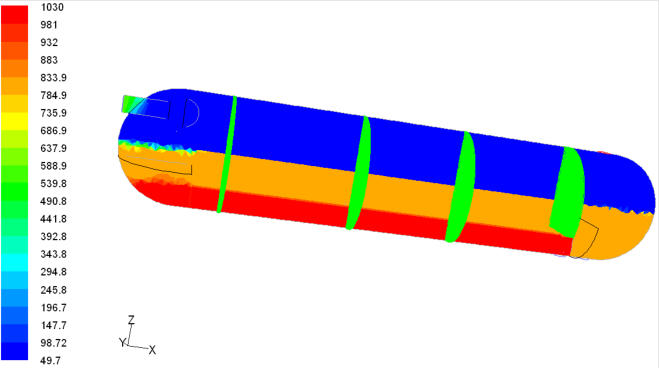

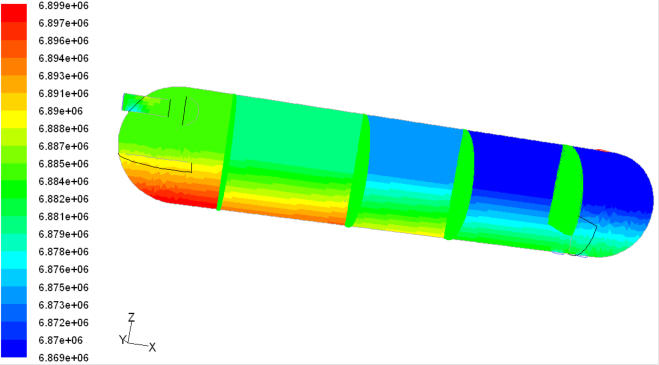

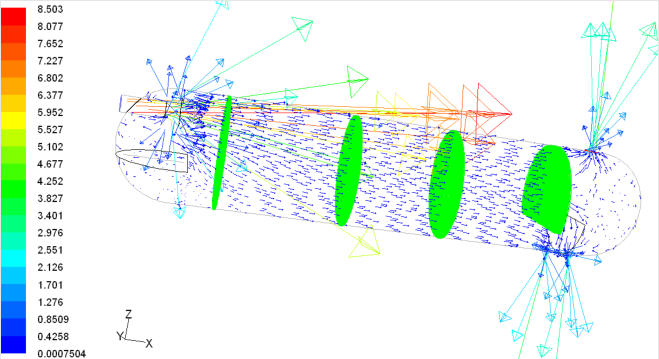

The

research

project

involved

the

CFD

simulation

of

four

pilot-plant-scale

two-phase

separators

and

one

industrial

scale

three-phase

separator,

including

all

the

installed

internals.

The

figures

below

show

some

of

the

produced

fluid

flow

profiles

for

the

large-scale

three-phase

separator.

There

was

excellent

agreement

between

simulated

phase

separation

behavior

and

the

empirical

observations and data gleaned from the pilot plant.

Contours of Density (kg/m

3

) in the Middle of a Large-Scale Three-Phase Separator.

Contours of Pressure (Pa) in the Middle of a Large-Scale Three-Phase Separator.

Vectors of Velocity (m/s) in the Middle of a Large-Scale Three-Phase Separator.

The

research

project

also

evaluated

the

classic

separator

design

methodologies

using

detailed

CFD

based

simulations,

and

proposed

improved

design

criteria.

In

order

to

specify

an

effective

optimum

separator,

a

useful

method

was

developed

for

estimation

of

the

droplet

sizes

used

to

calculate

realistic

separation

velocities

for

various

oilfield

conditions.

The

most

important

parameters

affecting

these

efficient

droplet

sizes

were

the

vapor

density

and

the

oil

viscosity.

In

contrast

with

classic

design

strategies,

the

CFD

simulation

results

showed

that

additional

residence

times

are

required

for

droplets

to

penetrate

through

the

interfaces.

Moreover,

the

Abraham

equation

should

be

used

instead

of

Stokes’

law

in

the

liquid-liquid

separation

calculations.

The

velocity

constraints

caused

by

re-entrainment

in

horizontal

separators

were

also

studied

via

comprehensive

CFD

simulations,

and

led

to

novel

correlations

for

the

re-entrainment

phenomenon.

Hence,

this

research

project

showed

the

benefits

that

CFD

analyses

can

provide

in

optimizing

the

design

of

new

separators

and

solving

problems

with

existing

designs.

For

more

information,

here

you find a complete and colourful Kindle version of this interesting PhD thesis.

References:

Anderson, J.D., “Computational Fluid Dynamics, The Basics with Applications”, McGraw-Hill,

1995.

Arnold, K., Stewart, M., “Surface Production Operations”, 3

rd

Edition, Elsevier, 2008.

Blezard, R.G., Bradburn, J., Clark, J.G., Cohen, D.H., Costaschuk, D., Downie, A.A., Fowler, P.,

Hassoun, L., Hunt, A.P., Kirton, D., Knight, F.I., Lach, J.R., Law, E.J., McDonald, P.A., Morrison,

A.K., Cairney, J.M., Naik, H., Sutton, W.J.E., Thompson, P., “Production Engineering”, in “Modern

Petroleum Technology”, R.A. Dawe (Ed.), 6

th

Edition, Vol. 1, Institution of Petroleum, John Wiley

& Sons, 2000.

Chin, R.W., Stanbridge, D.I., Schook, R., “Increasing Separation Capacity with New and Proven

Technologies”, Society of Petroleum Engineers, SPE-77495, 2002, 1-6.

Gerunda, A., “How to Size Liquid-Vapor Separators”, Chemical Engineering, May 4, 1981, 81-84.

Hooper, W.B., “Decantation”, Section 1.11 in “Handbook of Separation Techniques for Chemical

Engineers”, Ph.A. Schweitzer (Ed.), 3

rd

Edition, McGraw-Hill, 1997.

Lyons, W.C., Plisga, G.J. (Editors), “Standard Handbook of Petroleum and Natural Gas

Engineering”, Volume 2, Gulf Professional Publishing, 2005.

Monnery, W.D., Svrcek, W.Y., “Successfully Specify Three-Phase Separators”, Chem. Eng.

Progress, September, 1994, 29-40.

Pourahmadi Laleh, A., "CFD Simulation of Multiphase Separators", PhD Thesis, University of

Calgary, Calgary, Canada, 2010.

Sharratt, P.N., “Computational Fluid Dynamics and its Application in the Process Industries”,

Trans IChemE, 68-A, January, 1990, 13-18.

Shelley, S., “Computational Fluid Dynamics – Power to the People”, Chem. Eng. Progress, 103(4),

April, 2007, 10-13.

Sinnott, R.K., “Chemical Engineering Design” in “Coulson & Richardson’s Chemical

Engineering”, 2

nd

Edition, Butterworth-Heinemann, 1997.

Skelton, G.F., “Production”, in “Our Industry Petroleum”, Stockil, P.A. (Ed.), British Petroleum

Company Limited, 1977.

Smith, H.V., “Oil and Gas Separators”, in “Petroleum Engineering Handbook”, Bradley, H.B. (Ed),

Society of Petroleum Engineers, 1987.

Walas, S.M., “Process Vessels”, Chapter 18 in “Chemical Process Equipment Selection and

Design”, Butterworth-Heinemann, 1990.

Phase Separation Technology

Let’s

review

some

important

aspects

of

the

interesting

phase

separation technology:

The Role of Multiphase Separators

Multiphase Separator Terminology

The very first multiphase separator

The wide variety of separator designs

Phase Separation Zones

Operating Pressures and Capacities

Separator Internals

Common Operational Difficulties

CFD as a Separator Modeling Method

CFD Simulation of Multiphase Separators

The Role of Multiphase Separators

Multiphase

separators

are

one

of

the

most

prevalent

unit

operations

in

any

chemical

process.

Once

a

crude

oil

has

reached

the

surface,

the

main

purpose

of

the

surface

facilities

is

to

separate

the

produced

multiphase

stream

into

its

vapor

and

liquid

fractions.

Multiphase

separators

are

generally

the

first

process

equipment

in

an

oil

production

platform,

and

their

efficiency

influences

the

performance

of

all

downstream

equipment,

such

as

heaters,

compressors,

and

distillation

columns.

Thus,

oilfield

separators

play

a

key

role

in

the

production

capacity

of

entire

facility,

and

a

properly

sized

primary

multiphase

separator

can

increase

the capacity of the entire facility.

In

some

oilfields,

water

(brine)

is

not

produced

together

with

oil,

and

hence

only

the

gas

and

the

oil

need

to

be

separated

(two-phase

separation).

However,

usually,

three-

phase

separation

of

oil,

water,

and

gas

is

required

in

order

to

prepare

the

produced

multiphase

fluid

for

downstream

processing.

Multiphase Separator Terminology

Multiphase

separation

can

be

carried

out

through

various

oil

processing

equipment

with

the

specific

terminology

corresponding

to

each

system.

Hence,

it

is

worth

defining

the

most

important

multiphase

separators

in

the

oil

industry

before

proceeding.

The

conventional

oil

and

gas

separator,

which

is

normally

installed

on

a

production

facility

or

platform,

may

be

referred

to

as

“oil

and

gas

separator”,

“separator”,

“stage

separator”,

or

“trap”.

A

“knockout

vessel”

is

used

to

remove

either

water

or

all

liquid

from

the

well

fluid

flow.

An

“expansion

vessel”

is

the

first

stage

separator

vessel

usually

operated

at

a

low

temperature.

A

“flash

chamber”

or

“flash

vessel”

normally

refers

to

a

conventional

oil

and

gas

separator

operated

at

low

pressure

as

the

second

or

third

stage

of

the

multistage

separation.

A

“gas

scrubber”

is

an

oil

and

gas

separator

with

a

high

gas

to

liquid

ratio.

In

a

“wet-type

gas

scrubber”,

dust,

rust,

and

other

impurities

of

the

gas

phase

are

washed

using

a

bath

of

oil

or

other

liquid,

and

the

gas

flows

through

a

demister

to

further

remove

liquid

droplets

from

the

gas

stream.

A

“dry-

type

gas

scrubber”

or

“gas

filter”

is

equipped

with

demisters

and

other

coalescing

media

to

aid

in

the

removal

of

most

of

the liquid from a gas stream.

The very first multiphase separator

The

original

phase

separator

was

inclined,

very

long,

and

without

any

internal

separating

aids.

During

the

retention

time

(around

one

minute),

the

gas

and

oil

underwent

a

very

limited

separation.

Sir

Stephen

Gibson

designed

this

simple

phase

separator

and

also

the

multi-stage

separation

process.

He

was

the

first

to

put

this

process

into

operation

in

1930

at

the Haft-Kel oilfield in Iran (Skelton, 1977).

The wide variety of separator designs

A

wide

variety

of

separator

designs

and

configurations

for

multiphase

separators

in

both

vertical

and

horizontal

orientations

have

been

developed.

Various

parameters

such

as

space

and

operating

restrictions,

oilfield

variations,

potential

contaminants,

and

economic

evaluations

are

considered

in

the

design

of

a

multiphase

separation

system.

For

instance,

some

separators

may

be

equipped

with

special

impingement

internals

to

aid

the

separation

process.

The

figure

below

shows

some

different

common

designs

composed

of

“simple”,

“boot”,

“weir”,

and

“bucket

and

weir”.

These

designs

offer

a

variety

of

methods

to

control

the

interface

level

in

horizontal

three-phase

separators.

“Simple”

design

separator

can

easily

be

adjusted

to

handle

unexpected

changes

in

oil

or

water

density

or

flow

rates

(Arnold

and

Stewart,

2008).

A

boot,

typically,

is

used

when

the

water

fraction

is

not

substantial

(less

than

15-20%

of

total

liquid

by

weight),

and

a

weir

is

used

if

the

water

fraction

is

substantial

(Monnery

and

Svrcek,

1994).

The

bucket

and

weir

design

is

usually

used

when

interface

level

control

is

difficult

either

in

heavy

oil

applications

or

because

of

emulsions or paraffin problems (Arnold and Stewart, 2008

).

(a)

(b)

( c )

(d)

Different Common Designs of Horizontal Three-Phase

Separators; (a) “Simple”, (b) “Boot”, (c) “Weir”, and (d)

“Bucket and Weir”.

Phase Separation Zones

In

spite

of

the

variety

of

design

configurations

proposed

for

multiphase

separators,

the

phase

separation

process

is

accomplished

in

three

zones:

The

first

zone,

primary

separation,

uses

an

inlet

diverter

so

that

an

abrupt

change

in

flow

direction

and

velocity

causes

the

largest

liquid

droplets

to

impinge

on

the

diverter

and

then

drop

by

gravity.

In

this

zone,

the

bulk

of

the

liquid

phase

is

separated

from

the

gas

phase.

In

the

next

zone,

secondary

separation

zone,

gravity

separation

of

fine

droplets

occurs

as

the

vapor

and

liquid

phases

flow

through

the

main

section

of

the

separator

at

relatively

low

velocities

and

little

turbulence,

and

the

liquid

droplets

settle

out

of

the

gas

stream

due

to

gravity.

The

liquid

collection

section

in

the

bottom

half

of

separator

provides

the

retention

time

required

for

entrained

gas

bubbles

or

other

liquid

droplets

to

join

their

corresponding

phases

because

of

gravity

and

buoyancy.

This

section

also

provides

the

holdup

and

surge

volumes

for

safe

and

smooth

operation

of

the

separator.

Gas

flows

above

the

liquid

phase

while

entrained

small

liquid

droplets

are

again

separated

by

gravity.

The

final

zone,

coalescing

media,

is

designed

for

mist

elimination

in

which

very

fine

droplets

that

could

not

be

separated

in

the

gravity

settling

zone

are

separated

by

passing

the

gas

stream

through

a

mist

eliminator.

In

this

zone,

vanes,

wire

mesh

pad,

or

coalescing

plates

may

be

used

to

provide

an

impingement

surface

for

very

fine

droplets

to

coalesce

and

form

larger

droplets

which

can

be

separated out of gas stream by gravity.

Phase Separation Zones

Operating Pressures and Capacities

The

operating

pressure

of

separators

may

vary

from

a

high

vacuum

to

around

35

MPa

(Smith,

1987)

and

their

capacities

may

range

from

a

few

hundred

barrels

per

day

to

100000

barrels

per

day

or

more

(Skelton,

1977).

As

the

operating

pressure

of

a

separator

increases,

the

density

difference

between

the

liquid

and

gas

phases

decreases.

Therefore,

it

is

desirable

to

operate

multiphase

separators

at

as

low

a

pressure

as

is

consistent

with

other

process

conditions

and

requirements.

Most

multiphase

separators

operate

in

a

pressure range of 138 kPa to 10340 kPa (Smith, 1987).

Separator Internals

The

modern

separator

designs

have

much

higher

capacities

than

the

original

type

and

are

very

short

in

length

due

to

internals

such

as

inlet

diverters,

controls,

flow-distributing

baffles,

and

mist

extractors

which

enhance

the

separator

efficiency.

A

“weir”

design

horizontal

three-phase

separator

and

a

vertical

three-phase

separator,

both

with

the

installed

internals,

are

shown

in

the

Figures

below.

As

shown,

both

separators

are

equipped

with

inlet

diverters,

controls,

wire

mesh

demisters

and

pressure

relief

devices.

In

the

vertical

separator,

a

chimney

is

used

to

equalize

gas

pressure

between

the

lower

and

upper

sections

of

the

vessel.

Important common internals are explained as follows.

“Weir” Design Horizontal Three-Phase Separator with the

Installed Internals.

Vertical Three-Phase Separator with the Installed Internals.

Inlet Diverters

Usually

a

deflector

baffle

or

a

cyclone

is

used

as

inlet

diverter

in

the

separator.

Deflector

baffles

come

in

various

shapes

and

can

be

installed

at

different

angles.

However,

hemisphere

or

conical

designs

are

preferred

because

they

cause

fewer

disturbances

than

plates

or

angle

iron

and

reduce

re-entrainment

and

emulsion

problems

(Arnold

and

Stewart,

2008).

Cyclone

diverters

are

increasingly

used

in

oil

production

facilities

as

they

promote

foam

breaking

and

mist

elimination

while

performing

the

bulk

gas-liquid

separation

in

the

inlet

zone

(Chin

et

al.,

2002).

Hence,

cyclone

diverters

can

be

used

to

increase

the

operating

capacity of multiphase separators.

Controls

Separators

operate

at

a

predetermined

pressure

which

is

specified

by

economic

and

engineering

studies.

The

fixed

operating

pressure

in

a

separator

is

achieved

by

using

an

automatic

back

pressure

regulator

on

the

gas

outlet

line.

This

device

maintains

a

steady

operating

pressure

in

the

vessel.

The

liquid

level

controllers

and

liquid

outlet

control

valves

are

used

to

maintain

constant

oil

and

water

levels

in

the

separator.

Consequently,

the

operation

of

modern

separator systems is completely automatic.

Mist Eliminators

Droplets

with

diameters

of

100

micron

and

larger

will

generally

settle

out

of

the

gas

stream

in

most

average-sized

separators.

However,

mist

eliminators

are

usually

required

to

remove

smaller

droplets

from

the

gas

phase

(Smith,

1987).

As

95%

of

droplets

entrained

in

the

gas

stream

can

be

separated

in

economically-sized

separators

without

coalescing

media,

the

efficiency

can

be

increased

to

around

100%

by

installing

mist

eliminators

(Walas,

1990;

Sinnott,

1997;

Arnold

and

Stewart,

2008).

These

coalescing

media

can

consist

of

a

series

of

vanes,

a

knitted

wire

mesh

pad,

or

cyclonic

passages

to

remove

the

very

fine

droplets

from

the

gas

phase

by

impingement

on

a

large

surface

area

where

they

collect

and

collide

with

adjacent

droplets.

The

mechanisms

used

in

various

mist

eliminators

are

gravity

separation,

impingement,

change

in

flow

direction

and

velocity,

centrifugal

force,

coalescence,

and

filtering

(Smith,

1987).

Mist

eliminators

can

be

of

many

different

designs

exploiting one or more of these mechanisms.

The

wire

mesh

pads,

shown

below,

are

made

of

knitted

wire

mesh

and

are

installed

by

a

lightweight

support

inside

separators.

Since

the

early

1950s,

the

wire

mesh

demisters

have

been

used

in

natural

gas

processing

with

the

main

use

of

removing

fine

droplets

ranging

from

10

to

100

micron

in

diameter

from

the

gas

stream

(Smith,

1987).

Generally,

high

separation

efficiencies

at

a

low

capital

and

maintenance

cost

are

experienced

from

using

standard

wire

mesh

demisters.

The

pressure

drop

is

a

function

of

the

entrainment

load,

the

mesh

pad

design,

and

gas

velocity

but

does

not

usually

exceed

295

Pa

(Lyons

and

Plisga,

2005).

Although

pad

thicknesses

up

to

0.9

m

have

been

used,

a

pad

thickness

of

0.10

m

to

0.15

m

is

normally

sufficient

for

most

separator

applications

(Gerunda,

1981;

Walas,

1990;

Lyons

and

Plisga,

2005).

However,

the

“fouling”

tendency

of

wire

mesh

demisters

may

restrict

their

applications

to

gas

scrubbers

(Smith,

1987).

In

fact,

knitted

wire

mesh

may

foul

or

plug

from

paraffin

deposition

and

other

impurities

and

thus

reduce

separation

efficiency

dramatically

after

a

short

period

of

service.

In

such

cases,

vane-type

or

centrifugal

demisters

are used.

Wire Mesh Pad Mist Eliminator.

Vane-type

demisters,

shown

below,

are

widely

used

in

oil

and

gas

separators.

The

separation

mechanisms

used

in

most

of

vane-type

demisters

are

impingement,

change

in

flow

direction

and

velocity,

and

coalescence.

Vane-type

demisters

use

the

inertia

of

the

liquid

droplets

in

the

gas

stream

to

collect

a

film

of

liquid

on

the

vane

surface.

Vane-type

demisters

are

inexpensive

and

usually

will

not

plug

or

foul

with

paraffin

or

other

contaminants,

hence,

providing

a

good

separation

performance

under

widely

changing

field

conditions

(Smith,

1987).

Pressure

drop

across

the

vane-type

demisters

are

very

low,

ranging

from

250

Pa

to

1

kPa

(Smith,

1987).

Vane-Type Mist Eliminator.

Common Operational Difficulties

The

most

common

factors

which

can

reduce

separator

performance

are

very

high

or

very

low

liquid

level,

level

control

failure,

improper

design,

damaged

vessel

internals,

foam,

vortex

formation

in

liquid

outlet

zones,

plugged

liquid

outlets,

and

exceeding

the

design

capacity

of

the

vessel (Arnold and Stewart, 2008).

The

common

approaches

used

for

improving

the

separator

performance

in

difficult

cases,

as

proposed

by

Blezard

et

al.

(2000),

are

increasing

droplet

size

of

dispersed

phase

(e.g.,

by

promoting

coalescence),

inducing

a

high

acceleration

on

droplets

(e.g.,

by

using

centrifugal

force),

increasing

the

difference

between

fluid

densities

(e.g.,

by

introducing

diluents),

and

decreasing

the

viscosity

of

the

liquid

phases

(e.g.,

by

heating).

Some

of

these

approaches

may

be

combined

to

overcome

a

difficult

separation

task.

In

the

following,

some

different

measures

taken

for

operating

foamy, emulsified, or contaminated crude oils are outlined.

Foamy

crude

oils

hinder

liquid

level

control

and

also

reduce

the

separation

space

of

the

separator.

To

improve

the

separator

performance,

it

is

usually

advantageous

to

inject

a

silicon

defoaming

agent

into

the

foamy

oil

stream

(around

1x10

-6

m

3

for

1

m

3

of

oil)

before

it

enters

the

separator

(Skelton,

1977).

This

agent

breaks

up

the

foam

and

keeps

oil

from

being

carried

over

by

the

gas

phase,

leading

to

an

effective

increase

in

the

capacity

of

the

separator.

The

other

approaches

that

assist

in

breaking

the

foam

are

settling,

baffling,

heat,

and

centrifugal

force

(Smith,

1987).

For

separators

suffering

from

liquid

carryover

while

processing

foamy

crude

oils,

or

glycols,

amines,

and

similar

materials

(with

high

foaming

tendency),

a

dual

mist

eliminator

system

composed

of

a

vane-type

demister

at

a

lower

level

and

a

wire

mesh

pad

at

higher

level

with

a

gap

of

0.15

to

0.30

m

between them is usually used (Lyons and Plisga, 2005).

The

other

separation

difficulty

is

caused

by

thoroughly

emulsified

oil.

The

water

phase

enters

the

bottom

of

the

producing

well

and

usually

breaks

up

into

fine

droplets

on

its

way

to

the

surface.

These

fine

droplets

form

an

emulsion

with

the

oil

phase

which

can

lead

to

a

fully

emulsified

phase.

Separation

of

the

thoroughly

emulsified

phase

is

extremely

difficult,

and

it

is

often

recommended

that

as

much

of

the

water

as

possible

be

removed

at

the

well

head

(Skelton,

1977).

This

treatment

is

done

by

processing

the

crude

oil

through

a

large

vessel

(long

retention

time)

which

would

allow

the

larger

water

droplets

to

settle

out.

If

further

treatment

of

the

separated

oil

phase

is

necessary,

the

oil

phase

may

be

heated

to

help

break

down

the

emulsion.

Usually,

a

surface

tension

reducing

chemical

is

also

added

to

enhance

the

treatment.

Generally

the

combined

application

of

heat

and

chemicals

is

sufficient

to

reduce

the

water

and,

consequently,

the

salt

content

of

the

oil

phase

to

an

acceptable

level

(Skelton,

1977).

However,

sometimes

the

use

of

an

electrical

coalescing

media

may

be

necessary

to

achieve

specification

level

of

oil

product.

In

this

treatment

method,

the

oil-water

stream

is

exposed

to

an

electrical

field

which

agitates

the

water

droplets

and

causes

them

to

collide

and

coalesce

into

larger

droplets

and

then

to

settle

out

of

the

oil

phase.

The

resultant

water

concentration

in

the

effluent

oil

stream is usually less than 0.5% (Blezard et al., 2000).

Another

emulsion

problem

is

experienced

when

some

very

fine

particles

cause

a

stabilized

rag

layer

at

the

oil-water

interface.

In

order

for

the

separator

to

operate

properly,

the

rag

layer

must

be

regularly

broken

or

removed.

For

this

purpose,

some

techniques

such

as

filtration,

heating,

and

chemical injection are used (Hooper, 1997).

Contaminated

crude

oils

are

also

difficult

to

process.

The

most

common

contaminants

are

sand,

silt,

mud,

and

salt.

Medium-sized

sands

in

small

quantities

can

be

removed

by

an

oversized

vertical

settler.

The

residue

should

be

removed

periodically

by

draining

from

the

vessel

bottom.

Salt

may

be

removed

by

washing

the

oil

with

water

and

then

separating

the salty water from the oil phase.

CFD as a Separator Modeling Method

Computational

Fluid

Dynamics

(CFD)

is

inherently

connected

with

the

“fluid”

concept.

It

is

interesting

that

this

“fluid”

concept

can

still

be

defined

as

Isaac

Newton

proposed

more

than

300

years

ago

in

the

following

elegant

way:

“A

fluid

is

any

body

whose

parts

yield