Cost Estimation

The Role of Process Economics

The Levels of Capital Cost Estimation

Time Functionality of Capital Cost

Guthrie’s Modular Technique

Bare Module Cost for Process Vessels

The Role of Process Economics

Considering

the

fact

that

the

purpose

of

any

chemical

process

is

to

make

profit,

it

is

obvious

that

process

economics

need

be

accounted

for

seriously.

Always,

an

estimate

of

the

investment

required

and

the

cost

of

production

are

needed

before

the

profitability

of

a

project

can

be

assessed. There are three basic roles of process economics in process design:

1. Evaluation of design options.

2. Process optimization.

3. Overall project profitability.

The Levels of Capital Cost Estimation

Sinnott

and

Towler

(2007)

noted

that

the

accuracy

of

an

estimate

depends

on

the

amount

of

design

detail

available:

the

accuracy

of

the

cost

data

available;

and

the

time

spent

on

the

estimate.

There

are

five

levels

of

capital

cost

estimates

which

can

be

encountered

in

the

process

industries

(Turton

et al., 2018):

1. Detailed estimate, with accuracy of ±1% and when project is defined almost completely.

2. Definitive estimate, with accuracy of ±3% and when about 70% of project details is available.

3. Preliminary estimate, with accuracy of ±6% and when about 40% of project details is available.

4. Study estimate, with accuracy of ±12% and when about 15% of project details is available.

5. Order-of-magnitude estimate, with accuracy of ±20% and when about 2% of project is defined.

Feasibility

estimates

(order-of-magnitude

or

study

estimates)

are

made

to

compare

many

process

alternatives.

More

accurate

estimates

(preliminary

or

definitive

estimates)

are

made

for

the

most

profitable

processes

identified

in

the

feasibility

study.

Detailed

estimates

are

then

made

for

the

more

promising

alternatives

that

remain

after

the

preliminary

estimates.

Based

on

the

results

from

the

detailed

estimate,

a

final

decision

is

made

whether

to

go

ahead

with

the

construction

of

a

plant.

The

most

accurate

estimate

of

the

purchased

cost

of

a

piece

of

major

equipment

is

provided

by

a

current

price

quote

from

a

suitable

vendor

(a

seller

of

equipment).

The

next

best

alternative

is

to

use

cost

data

on

previously

purchased

equipment

of

the

same

type.

Another

technique,

sufficiently

accurate

for

study

and

preliminary

cost

estimates,

uses

summary

graphs

available

for

various types of common equipment.

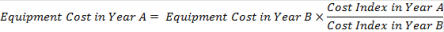

Time Functionality of Capital Cost

The

cost

of

materials

and

labor

is

always

subject

to

inflation.

All

cost-estimating

methods

use

historical

data,

and

are

themselves

forecasts

of

future

costs.

Some

method

has

to

be

used

to

update

old

cost

data

for

use

in

estimating

at

the

design

stage,

and

to

forecast

the

future

construction

cost

of

the

plant.

Published

cost

indices

are

usually

used

to

update

historical

cost

data

(Sinnott

and

Towler,

2007).

These

relate

present

costs

to

past

costs,

and

are

based

on

data

for

labor,

material

and energy costs published in government statistical digests.

Commonly

used

indices

are

the

Chemical

Engineering

Indexes

(1957–1959

index

=

100)

and

Marshall

and

Swift

(1926

index

=

100),

published

in

Chemical

Engineering

magazine

and

the

Nelson–Farrar

Cost

Indices

for

refinery

construction

(1946

index

=

100)

published

in

the

Oil

and

Gas

Journal.

The

Chemical

Engineering

Plant

Cost

Index

(CEPCI)

is

particularly

useful

for

equipment

costing

(Turton

et

al.,

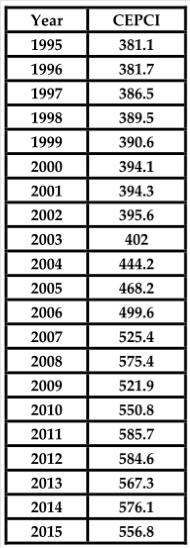

2018).

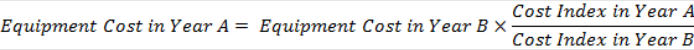

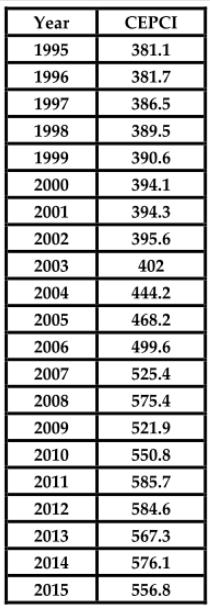

The

values

of

CEPCI

from

1995

to

2015

are

provided

in

the

following ta

ble.

Guthrie’s Modular Technique

The

modular

costing

technique

is

generally

accepted

as

the

best

for

making

preliminary

cost

estimates.

This

approach

was

introduced

by

Guthrie

in

the

late

1960s

and

early

1970s.

As

described

by

Turton

et

al.

(2018),

this

costing

technique

relates

all

costs

back

to

the

purchased

cost

of

equipment

evaluated

for

some

base

conditions.

Deviations

from

these

base

conditions

are

handled by using multiplying factors that depend on the following:

1. The specific materials of construction with the correction factor of f

M

2. The specific system pressure with the correction factor of f

P

3. The specific system temperature with the correction factor of f

T

For

equipment

made

from

materials

of

construction

other

than

Carbon

Steel

and/or

operating

at

non-ambient pressure and temperature, the values for correction factors are greater than 1.0.

In

order

to

account

for

both

direct

and

indirect

costs

of

an

installed

piece

of

equipment,

the

final

result

of

a

cost

estimation

is

usually

given

in

terms

of

the

Bare

Module

Cost

(BMC).

BMC

is

the

sum of the direct and indirect expenses for purchasing and installing a piece of equipment.

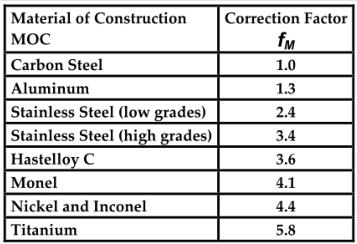

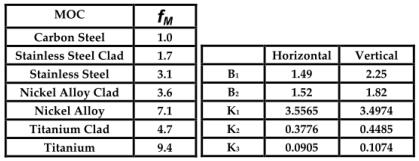

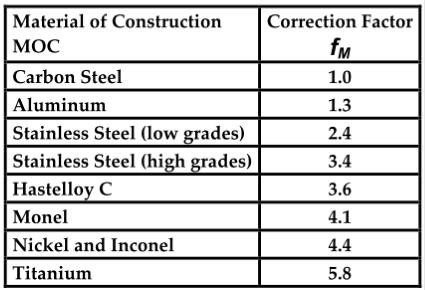

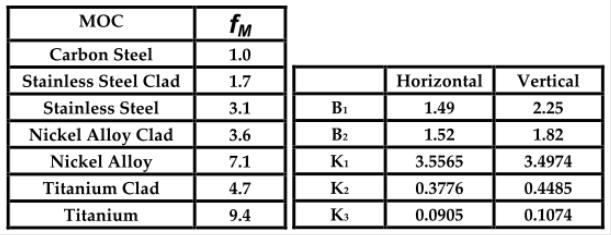

Materials

of

construction

have

a

significant

influence

on

the

capital

cost

of

equipment.

The

following

table

gives

some

approximate

average

factors

to

relate

the

different

materials

of

construction for equipment capital cost (Smith, 2005).

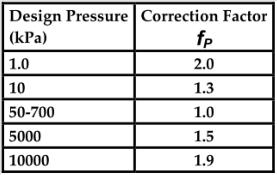

The

operating

pressure

also

impacts

equipment

capital

cost.

To

account

for

the

pressure

rating,

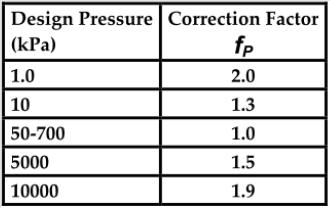

Smith (2005) provides the following typical correction factors:

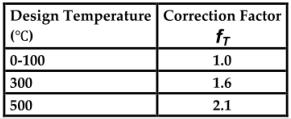

The

operating

temperature

also

influences

equipment

capital

cost.

This

is

caused

by,

amongst

other

factors,

a

decrease

in

the

allowable

stress

for

materials

of

construction

as

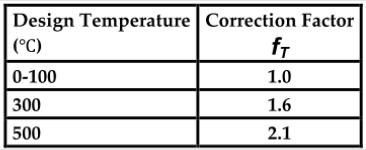

the

temperature

increases

(Smith,

2005).

Typical

factors

to

account

for

the

operating

temperature

are

presented

in

the following table:

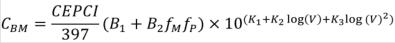

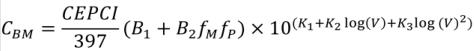

Bare Module Cost for Process Vessels

As

an

example,

Guthrie’s

modular

technique

is

used

for

cost

estimation

of

cylindrical

process

vessels.

The

bare

module

cost

for

this

equipment

is

given

by

the

following

equation

(Turton

et

al.,

2018):

In

this

equation,

V

is

the

vessel

volume

in

m

3

,

and

the

data

for

f

M

,

B

1

,

B

2

,

K

1

,

K

2

and

K

3

are

as

follows:

In

order

to

find

pressure

functionality

of

the

bare

module

cost,

one

must

consider

its

rigorous

mechanical

design

procedures.

The

relationship

between

design

pressure

and

wall

thickness

required

to

withstand

the

radial

stress

in

the

cylindrical

portion

of

the

vessel,

as

recommended

by

the ASME (2000), is given as:

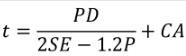

where

t

is

the

wall

thickness

in

m,

P

is

the

design

pressure

in

kPa,

D

is

the

diameter

of

the

vessel

in

m,

S

is

the

maximum

allowable

stress

of

material

in

kPa,

E

is

a

weld

efficiency,

and

CA

is

the

corrosion

allowance

(m).

The

weld

efficiency

is

dependent

on

the

type

of

weld

and

the

degree

of

examination

of

the

weld.

Typical

values

are

from

1.0

to

0.6.

The

corrosion

allowance

depends

on

the

service,

and

typical

values

are

from

3.15

to

6.3

mm

(0.125

to

0.25

inches).

Finally,

the

maximum

working

pressure

of

the

material

of

construction,

S,

is

dependent

not

only

on

the

material

but

also

on

the

operating

temperature.

Now,

we

consider

the

fact

that

the

cost

of

the

vessel

is

approximately

proportional

to

the

weight

of

the

vessel,

which

in

turn

is

proportional

to

the

vessel

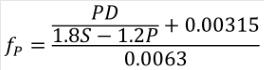

thickness. Therefore, with some simplifications, the following equation can be derived for f

P

:

If

f

P

is

calculated

to

be

less

than

1.0,

then

a

value

of

1.0

must

be

used

instead.

For

operating

pressures

less

than

50

kPa,

the

vessel

must

be

designed

to

withstand

full

vacuum,

that

is,

100

kPa

of

external

pressure

and

a

pressure

factor

of

1.25

should

be

used

for

such

conditions

(Turton

et

al.,

2018).

References:

Guthrie, K.M.,”Process Plant Estimating, Evaluation and Control”, Solana Beach, 1974.

Section VIII, ”ASME Boiler and Pressure Vessel Code”, ASME Boiler and Pressure Vessel

Committee, 2000.

Sinnott, R.K., Towler, G., “Chemical Engineering Design” in “Coulson & Richardson’s Chemical

Engineering”, Fifth Edition, Butterworth-Heinemann, 2007.

Smith, R., “Chemical Process Design and Integration”, Second Edition, John Wiley and Sons,

2005.

Turton, R., Shaeiwitz, J.A., Bhattacharyya, D., Whiting, W.B., "Analysis, Synthesis, and Design of

Chemical Processes", Fifth Edition, Pearson Education, 2018.

Ulrich, G.D., “A Guide to Chemical Engineering Process Design and Economics”, John Wiley and

Sons, 1984.

Cost Estimation

The Role of Process Economics

The Levels of Capital Cost Estimation

Time Functionality of Capital Cost

Guthrie’s Modular Technique

Bare Module Cost for Process Vessels

The Role of Process Economics

Considering

the

fact

that

the

purpose

of

any

chemical

process

is

to

make

profit,

it

is

obvious

that

process

economics

need

be

accounted

for

seriously.

Always,

an

estimate

of

the

investment

required

and

the

cost

of

production

are

needed

before

the

profitability

of

a

project

can

be

assessed.

There

are

three

basic

roles

of

process

economics in process design:

1. Evaluation of design options.

2. Process optimization.

3. Overall project profitability.

The Levels of Capital Cost Estimation

Sinnott

and

Towler

(2007)

noted

that

the

accuracy

of

an

estimate

depends

on

the

amount

of

design

detail

available:

the

accuracy

of

the

cost

data

available;

and

the

time

spent

on

the

estimate.

There

are

five

levels

of

capital

cost

estimates

which

can

be

encountered

in

the

process

industries

(Turton

et al., 2018):

1.

Detailed

estimate,

with

accuracy

of

±1%

and

when

project

is defined almost completely.

2.

Definitive

estimate,

with

accuracy

of

±3%

and

when

about

70% of project details is available.

3.

Preliminary

estimate,

with

accuracy

of

±6%

and

when

about 40% of project details is available.

4.

Study

estimate,

with

accuracy

of

±12%

and

when

about

15% of project details is available.

5.

Order-of-magnitude

estimate,

with

accuracy

of

±20%

and

when about 2% of project is defined.

Feasibility

estimates

(order-of-magnitude

or

study

estimates)

are

made

to

compare

many

process

alternatives.

More

accurate

estimates

(preliminary

or

definitive

estimates)

are

made

for

the

most

profitable

processes

identified

in

the

feasibility

study.

Detailed

estimates

are

then

made

for

the

more

promising

alternatives

that

remain

after

the

preliminary

estimates.

Based

on

the

results

from

the

detailed

estimate,

a

final

decision

is

made

whether

to

go

ahead with the construction of a plant.

The

most

accurate

estimate

of

the

purchased

cost

of

a

piece

of

major

equipment

is

provided

by

a

current

price

quote

from

a

suitable

vendor

(a

seller

of

equipment).

The

next

best

alternative

is

to

use

cost

data

on

previously

purchased

equipment

of

the

same

type.

Another

technique,

sufficiently

accurate

for

study

and

preliminary

cost

estimates,

uses

summary

graphs

available

for

various

types

of

common

equipment.

Time Functionality of Capital Cost

The

cost

of

materials

and

labor

is

always

subject

to

inflation.

All

cost-estimating

methods

use

historical

data,

and

are

themselves

forecasts

of

future

costs.

Some

method

has

to

be

used

to

update

old

cost

data

for

use

in

estimating

at

the

design

stage,

and

to

forecast

the

future

construction

cost

of

the

plant.

Published

cost

indices

are

usually

used

to

update

historical

cost

data

(Sinnott

and

Towler,

2007).

These

relate

present

costs

to

past

costs,

and

are

based

on

data

for

labor,

material

and

energy

costs

published

in

government

statistical digests.

Commonly

used

indices

are

the

Chemical

Engineering

Indexes

(1957–1959

index

=

100)

and

Marshall

and

Swift

(1926

index

=

100),

published

in

Chemical

Engineering

magazine

and

the

Nelson–Farrar

Cost

Indices

for

refinery

construction

(1946

index

=

100)

published

in

the

Oil

and

Gas

Journal.

The

Chemical

Engineering

Plant

Cost

Index

(CEPCI)

is

particularly

useful

for

equipment

costing

(Turton

et

al.,

2018).

The

values

of

CEPCI

from

1995

to

2015

are

provided in the following ta

ble.

Guthrie’s Modular Technique

The

modular

costing

technique

is

generally

accepted

as

the

best

for

making

preliminary

cost

estimates.

This

approach

was

introduced

by

Guthrie

in

the

late

1960s

and

early

1970s.

As

described

by

Turton

et

al.

(2018),

this

costing

technique

relates

all

costs

back

to

the

purchased

cost

of

equipment

evaluated

for

some

base

conditions.

Deviations

from

these

base

conditions

are

handled

by

using

multiplying

factors

that depend on the following:

1.

The

specific

materials

of

construction

with

the

correction

factor of f

M

2.

The

specific

system

pressure

with

the

correction

factor

of

f

P

3.

The

specific

system

temperature

with

the

correction

factor

of f

T

For

equipment

made

from

materials

of

construction

other

than

Carbon

Steel

and/or

operating

at

non-ambient

pressure

and

temperature,

the

values

for

correction

factors

are

greater

than 1.0.

In

order

to

account

for

both

direct

and

indirect

costs

of

an

installed

piece

of

equipment,

the

final

result

of

a

cost

estimation

is

usually

given

in

terms

of

the

Bare

Module

Cost

(BMC).

BMC

is

the

sum

of

the

direct

and

indirect

expenses

for purchasing and installing a piece of equipment.

Materials

of

construction

have

a

significant

influence

on

the

capital

cost

of

equipment.

The

following

table

gives

some

approximate

average

factors

to

relate

the

different

materials

of construction for equipment capital cost (Smith, 2005).

The

operating

pressure

also

impacts

equipment

capital

cost.

To

account

for

the

pressure

rating,

Smith

(2005)

provides

the

following typical correction factors:

The

operating

temperature

also

influences

equipment

capital

cost.

This

is

caused

by,

amongst

other

factors,

a

decrease

in

the

allowable

stress

for

materials

of

construction

as

the

temperature

increases

(Smith,

2005).

Typical

factors

to

account

for

the

operating

temperature

are

presented

in

the

following table:

Bare Module Cost for Process Vessels

As

an

example,

Guthrie’s

modular

technique

is

used

for

cost

estimation

of

cylindrical

process

vessels.

The

bare

module

cost

for

this

equipment

is

given

by

the

following

equation

(Turton et al., 2018):

In

this

equation,

V

is

the

vessel

volume

in

m

3

,

and

the

data

for f

M

, B

1

, B

2

, K

1

, K

2

and K

3

are as follows:

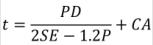

In

order

to

find

pressure

functionality

of

the

bare

module

cost,

one

must

consider

its

rigorous

mechanical

design

procedures.

The

relationship

between

design

pressure

and

wall

thickness

required

to

withstand

the

radial

stress

in

the

cylindrical

portion

of

the

vessel,

as

recommended

by

the

ASME (2000), is given as:

where

t

is

the

wall

thickness

in

m,

P

is

the

design

pressure

in

kPa,

D

is

the

diameter

of

the

vessel

in

m,

S

is

the

maximum

allowable

stress

of

material

in

kPa,

E

is

a

weld

efficiency,

and

CA

is

the

corrosion

allowance

(m).

The

weld

efficiency

is

dependent

on

the

type

of

weld

and

the

degree

of

examination

of

the

weld.

Typical

values

are

from

1.0

to

0.6.

The

corrosion

allowance

depends

on

the

service,

and

typical

values

are

from

3.15

to

6.3

mm

(0.125

to

0.25

inches).

Finally,

the

maximum

working

pressure

of

the

material

of

construction,

S,

is

dependent

not

only

on

the

material

but

also

on

the

operating

temperature.

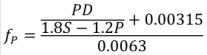

Now,

we

consider

the

fact

that

the

cost

of

the

vessel

is

approximately

proportional

to

the

weight

of

the

vessel,

which

in

turn

is

proportional

to

the

vessel

thickness.

Therefore,

with

some

simplifications,

the

following equation can be derived for f

P

:

If

f

P

is

calculated

to

be

less

than

1.0,

then

a

value

of

1.0

must

be

used

instead.

For

operating

pressures

less

than

50

kPa,

the

vessel

must

be

designed

to

withstand

full

vacuum,

that

is,

100

kPa

of

external

pressure

and

a

pressure

factor

of

1.25

should be used for such conditions (Turton et al., 2018).

References:

Guthrie, K.M.,”Process Plant Estimating, Evaluation and

Control”, Solana Beach, 1974.

Section VIII, ”ASME Boiler and Pressure Vessel Code”,

ASME Boiler and Pressure Vessel Committee, 2000.

Sinnott, R.K., Towler, G., “Chemical Engineering Design” in

“Coulson & Richardson’s Chemical Engineering”, Fifth

Edition, Butterworth-Heinemann, 2007.

Smith, R., “Chemical Process Design and Integration”,

Second Edition, John Wiley and Sons, 2005.

Turton, R., Shaeiwitz, J.A., Bhattacharyya, D., Whiting, W.B.,

"Analysis, Synthesis, and Design of Chemical Processes",

Fifth Edition, Pearson Education, 2018.

Ulrich, G.D., “A Guide to Chemical Engineering Process

Design and Economics”, John Wiley and Sons, 1984.