Separator Sizing

Here we review important guidelines and procedures for sizing multiphase separators:

General Guidelines

Droplet Settling Theory

Liquid Retention Time

Sizing Procedure

Improvements Offered by CFD Simulations

General Guidelines

Orientation

For

practical

design

of

separators,

it

is

necessary

to

compare

both

horizontal

and

vertical

orientation

designs

to

determine

which

design

is

more

economical

(Svrcek

and

Monnery,

1993).

However,

the

following

general

guidelines

are

recommended

to

be

considered

while

sizing

multiphase separators.

Vertical orientation

advantages

:

•

Occupy little plot space

•

Easier than horizontal separators to transport and install

•

Used

when

there

is

small

liquid

load,

limited

plot

space,

or

where

ease

of

level

control

is

desired (Evans, 1974)

•

Preferred for operating either low or very high gas/oil ratio fluids (Arnold and Stewart, 2008)

Horizontal orientation

advantages

:

•

Higher operating capacity, and processing capabilities

•

Preferred

when

emulsions,

foam,

or

high

gas/oil

ratio

fluids

are

present

(Arnold

and

Stewart,

2008)

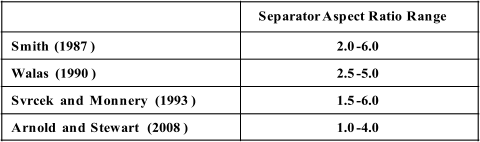

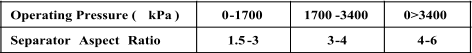

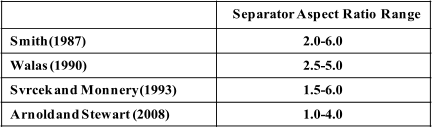

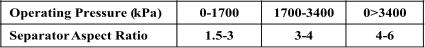

Separator Aspect Ratio (Length/Diameter)

Plot restrictions and economic measures specify the separator aspect ratio. Different ranges have

been suggested as shown in the table below

Economic

studies

provided

the

separator

aspect

ratio

as

a

function

of

the

operating

pressure

(Walas, 1990; Svrcek and Monnery, 1993). The recommended values presented in the table

.

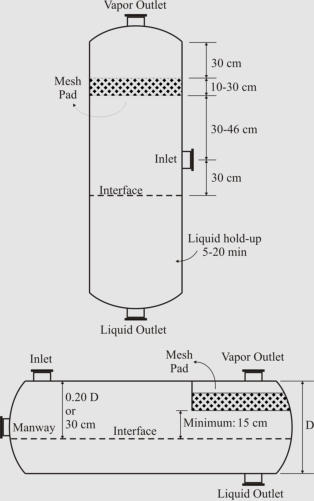

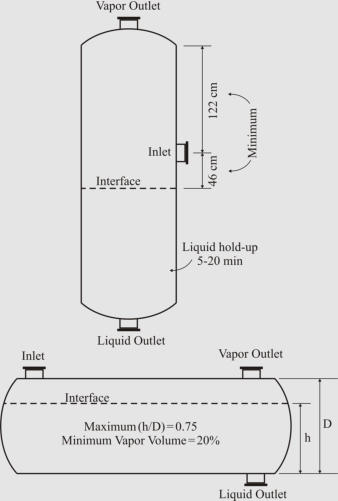

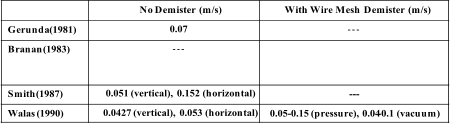

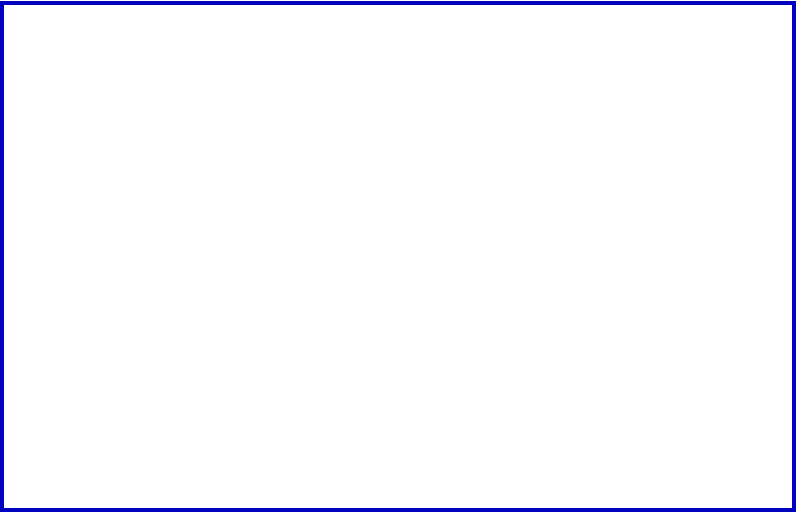

The

figures

below

show

illustrated

guidelines

proposed

by

Walas

(1990)

and

Watkins

(1967)

for

two-phase separators with and without demisters, respectively.

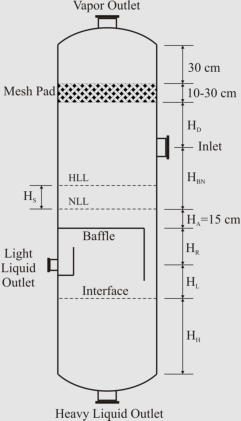

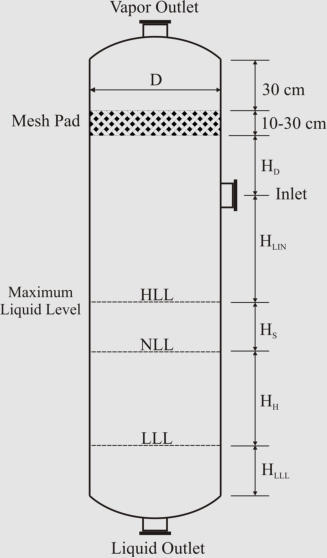

Design Heuristics Proposed by Walas (1990) for Two-Phase Separators Equipped with Wire Mesh

Demisters.

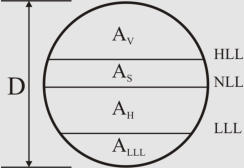

Design Heuristics Proposed by Watkins (1967) for Two-Phase Separators.

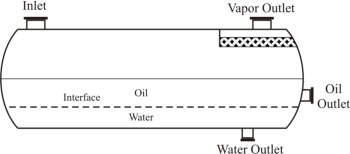

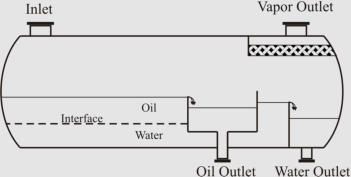

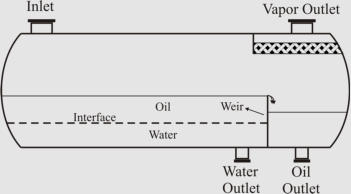

There

are

also

some

general

guidelines

for

choosing

among

different

horizontal

separators

(see

the

figure

below)

which

are

worth

mentioning:

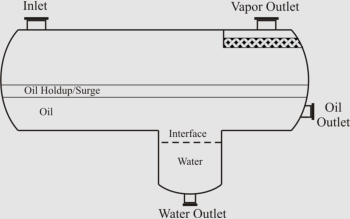

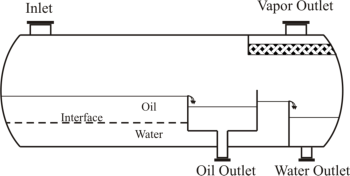

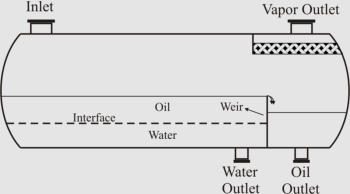

As

per

Arnold

and

Stewart

(2008),

while

the

simple

design

is

easily

adjustable

to

handle

unexpected

changes

in

liquid

density/flow

rates,

the

bucket

&

weir

design

is

used

when

interface

level

control

is

difficult

(emulsions

or

paraffin

problems).

If

heavy

liquid

mass

fraction

is

substantial,

the

weir

design

is

preferable,

but

the

boot

design is preferred when heavy liquid mass fraction is less than 20% (Monnery and Svrcek, 1994).

(

a

)

(

b)

(

c) (

d)

Different Common Designs of Horizontal Three-Phase Separators; (a) “Simple”, (b) “Boot”, (c)

“Weir”, and (d) “Bucket and Weir”.

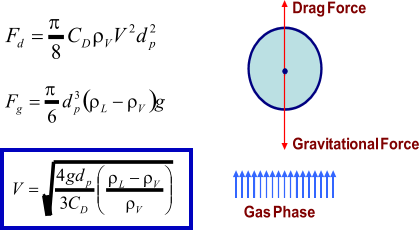

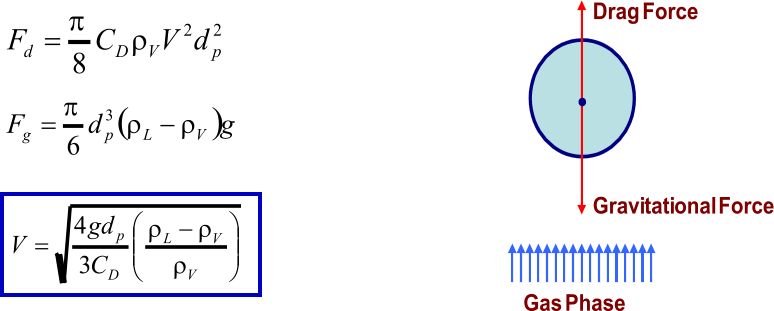

Droplet Settling Theory

Liquid Droplet in Vapor Phase

The

force

balance

between

drag

and

gravitational

forces

exerted

on

a

liquid

droplet

leads

to

its

terminal settling velocity

:

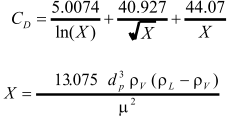

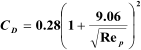

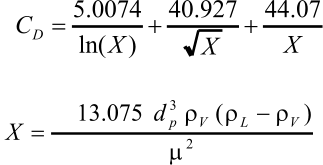

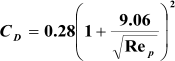

Drag

coefficient

for

vapor-liquid

separation

can

be

obtained

from

the

diagram

proposed

by

GPSA.

This

diagram

is

applicable

if

Re

p

is

between

0.4

and

1500.

The

diagram

curve

can

be

regressed as shown in the following with SI units (Monnery and Svrcek, 2000)

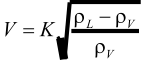

:

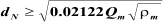

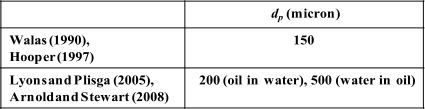

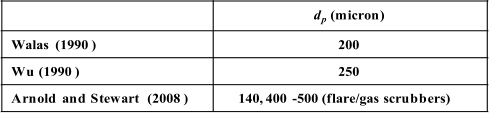

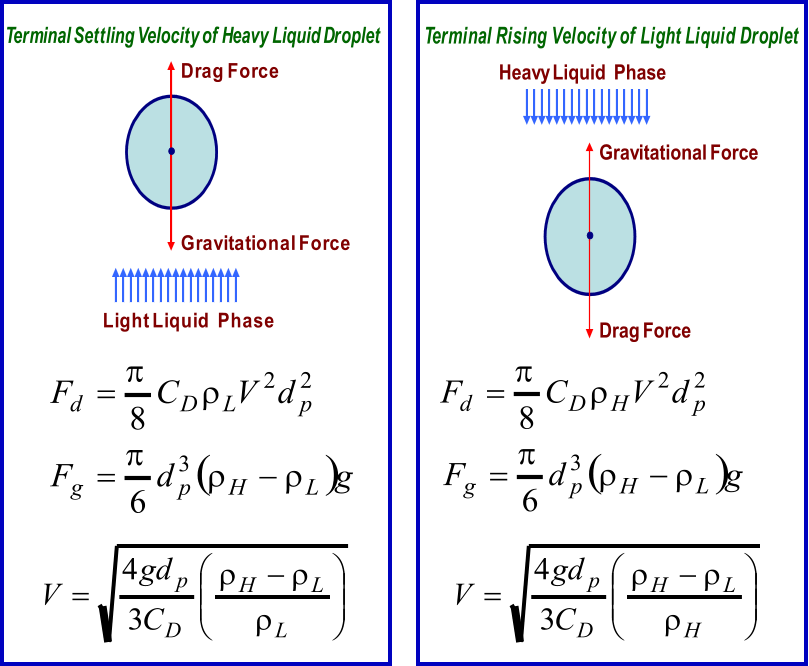

As

presented

in

the

table,

there

are

different

values

recommended

by

the

field

researchers

for

the

design droplet size

.

In

separator

sizing

literature,

it

is

very

common

to

rearrange

the

settling

velocity

equation

introducing

a

K

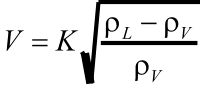

coefficient,

known

as

the

settling

velocity

coefficient.

This

leads

to

the

Sauders-

Brown equatio

n:

Different

values

are

suggested

in

the

literature

to

be

used

for

the

settling

velocity

coefficient.

The

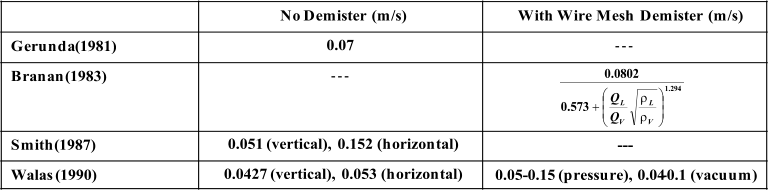

following table provides some of these suggestion

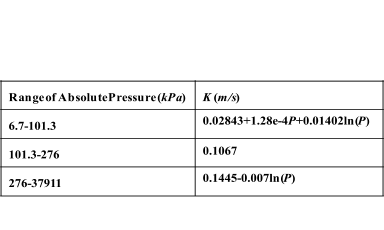

s:

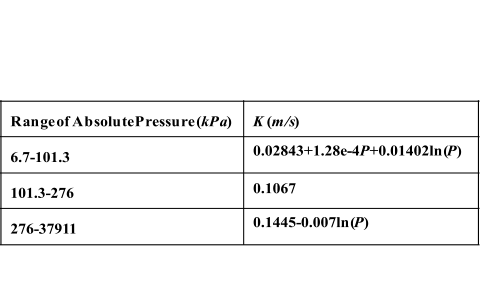

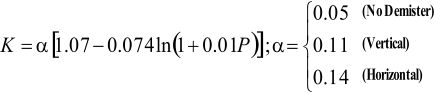

More

sophisticated

approaches

recommend

that

pressure

functionality

need

be

considered

for

the

settling

velocity

coefficient.

The

approaches

proposed

by

York

Mist

Eliminator

Company

and

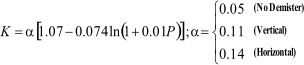

GPSA are given at below (Svrcek and Monnery, 1993):

York Mist Eliminator Compan

y

GPS

A

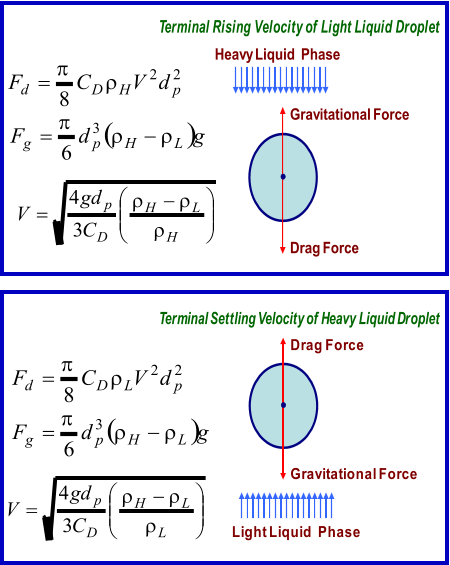

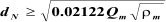

Liquid Droplet in Liquid Phase

Similar

to

vapor-liquid

separation,

the

force

balance

between

drag

and

gravitational

forces

exerted on a liquid droplet leads to its terminal velocity

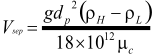

:

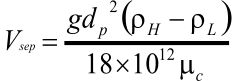

It

is

generally

assumed

that

Re

p

is

lower

than

0.1

and

Stokes’

law

can

be

used

for

calculating

the

drag coefficient: C

D

= 24/Re

p

This assumption results in a very simple equation for the liquid droplet terminal velocit

y:

Some design droplet sizes recommended in the literature are shown in the tabl

e.

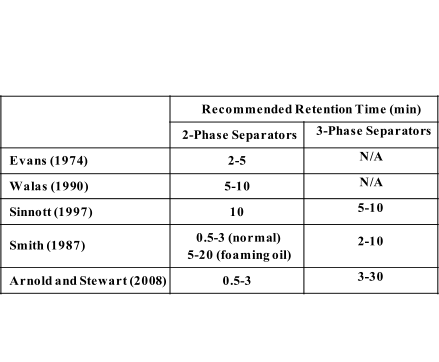

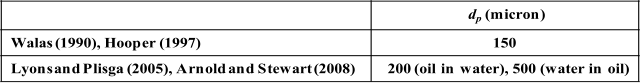

Liquid Retention Time

In

order

to

handle

upstream

or

downstream

variations

and

establish

smooth

and

safe

operation

of

downstream

facilities,

an

adequate

liquid

retention

time

need

be

assumed.

This

assumption

may

be

based

on

experience,

scale

model

predictions,

or

field

data.

Liquid

retention

time

is

combined

from

holdup

and

surge

time.

Holdup,

considered

for

smooth

and

safe

operation

of

downstream

facilities,

is

defined

as

the

time

it

takes

to

reduce

the

liquid

level

from

normal

to

low

liquid

level

by

closing

inlet

flow

while

maintaining

a

normal

outlet

flow.

Surge

time,

considered

for

handling

upstream

or

downstream

variations,

is

defined

as

the

time

it

takes

to

increase

the

liquid

level

from

normal

to

high

liquid

level

by

closing

outlet

flow

while

maintaining

a

normal

inlet

flow.

Some

rules-of-thumb

have

been

suggested

at

literature

which

are

not

in

reasonable

agreement

with each other as shown in the table

.

In

the

more

pragmatic

approach

presented

by

Svrcek

and

Monnery

in

1993

and

1994,

low

liquid

level

is

first

set

based

on

the

operating

pressure

and

diameter

(typical:

6-12

in).

Then,

holdup

(typical:

2-10

min)

and

surge

times

(typical:

1-5

min)

are

specified

based

on

the

service

and

quality

of the personnel and instrumentation (with impact factor of 1.0 – 1.5 altogether).

Sizing Procedure

The

sizing

approach

outlined

here

is

proposed

by

Svrcek

and

Monnery

through

two

internationally

acclaimed

papers

in

1993

and

1994.

It

is

an

algorithmic

method

for

designing

the

most

economical

separator.

Among

the

classic

methods,

the

method

offers

the

most

comprehensive

approach

while

benefiting

from

the

accepted

industrial

design

guidelines.

As

explained

in

the

following,

height

adjustments

are

made

for

sizing

vertical

separators

and

iterative calculations are performed for finding the most economical horizontal separator.

Sizing Vertical Two-Phase Separat

o

r

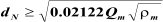

1. Calculate the terminal settling velocity of liquid droplets.

2. Set the vapor velocity equal to 75% of the terminal

settling velocity.

3. Calculate the vessel diameter based on the vapor

volumetric flow-rate and the vapor velocity.

4. Obtain low liquid level height (typical: 6-12 in).

5. Calculate the height from LLL to NLL based on the

required holdup time (typical: 2-10 min).

6. Calculate the height from NLL to HLL based on the

surge time (typical: 1-5 min).

7. Calculate the height from HLL to the inlet nozzle

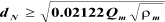

centerline based on the inlet nozzle size which can be

calculated as:

8. Assume the disengagement height (H

D

) to be about

0.5D (Min: 42 in or 30 in with demister).

9. Calculate the vessel height. If the aspect ratio is not

in the range of 1.5-6.0, increase the diameter (to

decrease the aspect ratio) or increase vapor

disengagement height (to increase the aspect ratio) and

fix the problem.

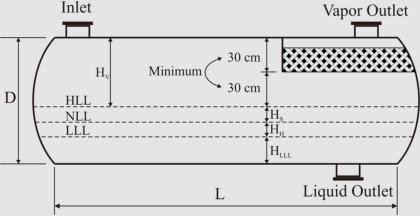

Sizing Horizontal Two-Phase Separat

or

In

horizontal

arrangement,

cross-sectional

area

of

the

vessel

is

shared

by

vapor-liquid

disengagement

area

and

areas

for

liquid

retention and low liquid level.

Here is the iterative algorithmic method for sizing:

1. Calculate the terminal settling velocity of liquid droplets. Use

0.75U

T

as the settling velocity (25% contingency).

2. Calculate the holdup volume based on the required holdup

time (typical: 2-10 min) and liquid volumetric flow rate.

3. Calculate the surge volume based on the surge time (typical: 1-5 min) and liquid volumetric

flow rate.

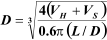

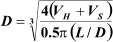

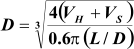

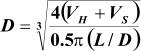

4. Assume an aspect ratio (L/D) based on the operating pressure and calculate an initial diameter:

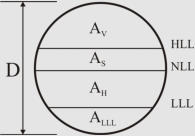

5. Obtain LLL (typical: 6-12 in) and calculate A

LLL

.

6. Set H

V

to the larger of 0.2D or 1 ft (no demister), 2 ft (with demister). Calculate A

V

.

7. Calculate L to accommodate the liquid retention volume: L = (V

H

+V

S

)/(A

T

-A

V

-A

LLL

)

8. Calculate the minimum length required for vapor-liquid separation: L

min

= (Q

V

/A

V

)(H

V

/U

T

)

9. If L < 0.8L

min

, increase H

V

and go to step 7. Else if L < L

min

, set L = L

min

. Else if L > 1.2L

min

,

decrease H

V

(if acceptable), and go to step 7. Else (L > L

min

), L is acceptable.

10. If L/D < 1.5, decrease D and go to step 5. Else if L/D > 6, increase D and go to step 5.

11. Calculate the approximate vessel weight based on the thickness and surface area of shell and

heads.

12. In order to find the optimum case (the minimum weight), change the vessel diameter by 6 in

increments and repeat the calculations from step 5 while keeping the aspect ratio in the range of

1.5 to 6.0.

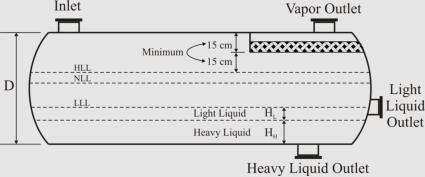

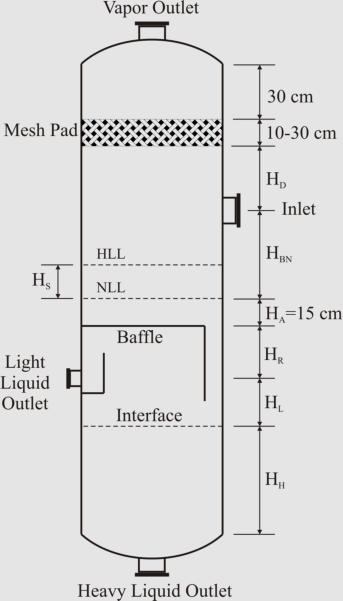

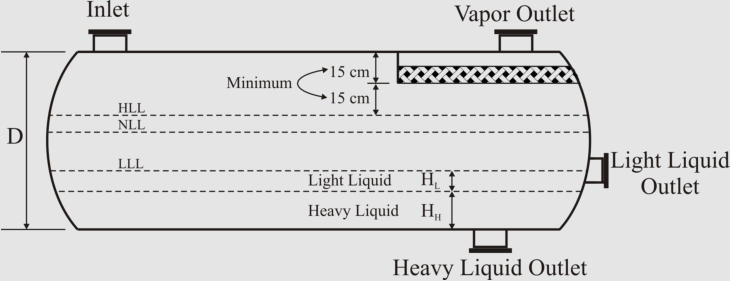

Sizing Vertical Three-Phase Separator

1. Calculate the terminal settling velocity of light liquid droplets.

2. Set the vapor velocity equal to 75% of the terminal settling velocity.

3. Calculate the vessel diameter based on the vapor

volumetric flow-rate and the vapor velocity.

4. Calculate the separation velocities of both liquid

phases through each other.

5. Set the thickness of liquid phases (HLL = HHL =

0.3 m as minimum), and calculate the separation

times for the liquid droplets (t

HL

and t

LH

).

6. Calculate the cross-sectional areas of the liquid

phases. Note, A

H

is the same as the vessel cross-

sectional area (A

H

= A), but the area allotted to baffle

plate down-comer should be subtracted from A to

obtain A

L

.

7. Calculate the residence time of the light liquid:

t

RL

= H

L

A

L

/Q

LL

. If t

RL

< t

HL

increase the vessel diameter

so that t

RL

= t

HL

.

8. Calculate the residence time of the heavy liquid:

t

RH

= H

H

A

H

/Q

HL

. If t

RH

< t

LH

increase the vessel

diameter so that t

RH

= t

LH

.

9. Calculate the height of light liquid phase above the

outlet (H

R

) based on the required holdup time

(typical: 2-10 min) and liquid flow rate.

10. Calculate the surge height (H

S

) based on the surge time (typical: 1-5 min) and liquid flow rate.

11. Set liquid level above baffle (H

A

= 0.15 m minimum).

12. Calculate the height from NLL to the inlet nozzle centerline based on the surge height (H

S

) and

the inlet nozzle size which can be calculated as:

13. Assume the disengagement height (H

D

) to be about 0.5D (minimum: 24”+0.5d

N

with demister

or 36”+0.5d

N

no demister).

14. Calculate the vessel height. If the aspect ratio is not in the range of 1.5-6.0, increase the

diameter (to decrease the aspect ratio) or height (to increase the aspect ratio) of the separator and

fix the problem.

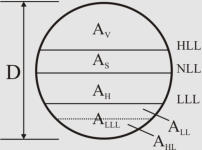

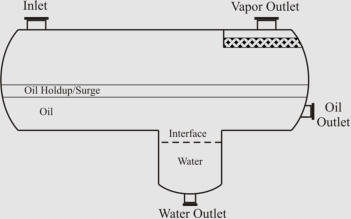

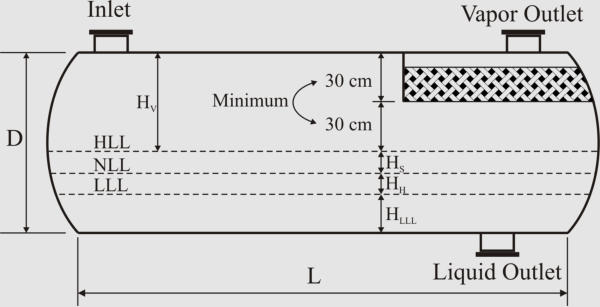

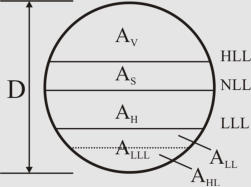

Sizing Horizontal Three-Phase Separator

In

order

to

show

the

sizing

strategy,

only

“simple”

horizontal

separator

is

presented

here.

The

other

arrangements,

i.e.

“weir”,

“boot”,

and

“bucket

&

weir”,

follow

the

same

strategy

but

require

further effort for sizing their compartments.

In

horizontal

arrangement,

cross-se

c

tional

area

of

the

vessel

is

shared

by

vapor-liquid

disengagement

area

and

areas

for

liquid

retention

and

low

liquid level. Here is the iterative algorithmic method for sizing:

1. Calculate the terminal settling velocity of light liquid

droplets. Use 0.75U

T

as the settling velocity (25% contingency).

2. Calculate the holdup volume based on the required holdup

time (typical: 2-10 min) and liquid volumetric flow rate.

3. Calculate the surge volume based on the surge time (typical:

1-5 min) and liquid volumetric flow rate.

4. Assume an aspect ratio (L/D) based on the operating pressure and calculate an initial diameter:

5. Set the thickness of liquid phases (minimum: HLL = HHL = 0.3 m), and calculate A

LLL

= A

HL

+A

LL

.

6. Set H

V

to the larger of 0.2D or 1 ft (no demister), 2 ft (with demister). Calculate A

V

.

7. Calculate L to accommodate the liquid retention volume: L = (V

H

+V

S

)/(A

T

-A

V

-A

LLL

)

8. Calculate the minimum length required for vapor-liquid separation: L

min

= (Q

V

/A

V

)(H

V

/U

T

)

9. If L < 0.8L

min

, increase H

V

and go to step 7. Else if L < L

min

, set L = L

min

. Else if L > 1.2L

min

,

decrease H

V

(if acceptable), and go to step 7. Else (L > L

min

), L is acceptable.

10. Calculate the liquid-liquid separation times: t

HL

= (D-H

V

-HHL)/U

HL

and t

LH

= HHL/U

LH

11. Calculate the light liquid residence time: t

RL

= L(A-A

V

-A

HL

)/Q

LL

.

If t

RL

< t

HL

increase L so that t

RL

= t

HL

.

12. Calculate the heavy liquid residence time: t

RH

= LA

HL

/Q

HL

.

If t

RH

< t

LH

increase L so that t

RH

= t

LH

.

13. If L/D < 1.5, decrease D (if acceptable) and go to step 5. Else if L/D > 6, increase D and go to step

5.

14. Calculate the approximate vessel weight based on thickness and surface area of shell and

heads.

15. In order to find the optimum case (the minimum weight), change the vessel diameter by 6”

increments, and repeat the calculations from step 5 while keeping the aspect ratio in the range of

1.5 to 6.0.

Improvements Offered by CFD Simulations

We

have

recently

developed

Computational

Fluid

Dynamics

(CFD)

based

simulation

of

multiphase

separators.

In

order

to

study

selected

aspects

of

phase

separation,

the

focus

was

placed

on

hydrocarbon-water

systems,

and

the

oilfield

separator

data

ranging

from

light

oil

conditions

to

heavy

oil

conditions

were

used

in

these

multiphase

separator

simulations.

An

efficient

combination

of

two

multiphase

simulation

models

available,

VOF

and

DPM,

with

appropriate

model

assumptions

and

settings

was

used.

Two

independent

sets

of

CFD

simulations,

one

for

vapor-liquid

separation

and

the

other

for

liquid-liquid

separation,

were

performed

using

simple

and efficient grid systems.

When

compared

to

classic

design

strategies,

CFD

simulations

indicated

that

additional

residence

times

are

necessary

for

droplets

to

pass

through

the

interfaces.

The

interface

residence

time

may

be as high as around 100 s depending on the fluid properties.

In

the

vapor-liquid

separation

compartment,

the

efficient

droplet

size

and

the

appropriate

extra

vapor

residence

time

(for

droplet

penetration

through

the

interface)

were

estimated

as

a

function

of

the

vapor

density.

It

was

shown

that

for

the

three-phase

separator

case

study,

the

efficient

separation

of

oil

droplets

from

gas

phase

results

in

total

separation

of

water

droplets

from

the

gas

phase.

For

the

liquid-liquid

separation

process,

the

upper

limit

of

Stokes’

law

(Re

p

<

0.1)

was

exceeded

in

several case studies. Hence, Abraham equation (Re

p

< 2000) was recommended to be used inste

ad:

Using

the

Abraham

equation

in

liquid-liquid

separation

calculations,

the

efficient

droplet

size

was

estimated

based

on

continuous

phase

viscosity.

Hence,

for

water

droplets,

a

linear

regression

fit

based

on

the

oil

phase

viscosity

was

developed.

An

oil

droplet

size

of

around

600

micron

can

be

assumed

if

the

Abraham

equation

is

used

for

estimation

of

the

rising

velocity

of

oil

droplets

out

of

the

water

phase.

Furthermore,

it

was

shown

that

the

use

of

Stokes’

law

for

interpretation

of

CFD

results

does

lead

to

a

weak

correlation

between

efficient

droplet

sizes

and

continuous

phase

viscosities.

A

comprehensive

CFD-based

study

on

the

velocity

constraints

caused

by

re-entrainment

in

horizontal

separators

confirmed

that,

as

per

practical

experience,

high

vapor

densities

and

high

oil

viscosities reduce the maximum safe velocity of the vapor phase.

The

results

of

CFD

simulations,

using

all

the

feasible

horizontal

designs

and

selected

oilfield

conditions,

indicated

that

the

oil

phase

does

not

re-entrain

the

water

droplets,

but

the

oil

droplets

may

be

“re-entrained”

by

the

water

phase

at

a

high

velocity.

It

was

also

elucidated

that

the

geometry

of

water

phase

compartment

in

horizontal

separators

is

a

key

factor

affecting

the

liquid-

liquid

re-entrainment

phenomenon.

The

maximum

safe

cross-sectional

velocity

of

the

water

phase

was a linear function of the oil viscosity.

Finally,

it

was

shown

that

the

algorithmic

design

method

of

Monnery

and

Svrcek

(1994)

can

be

modified

to

use

CFD

simulation

results

to

specify

a

realistic

optimum

separator

design/size.

This

fact

was

elaborated

through

the

mobile/desktop

applications

developed

for

sizing

two-phase

and

three-phase separators. Please click

here

for more information.

The

serious

process

engineers

can

download

a

complete

and

colourful

version

of

this

interesting

PhD thesis from

here

to acquire more details on practical sizing formula.

References:

Abraham, F.F., “Functional Dependence of Drag Coefficient of a Sphere on Reynolds Number”,

Physics of Fluids, 13, 1970, 2194-2195.

Arnold, K., Stewart, M., “Surface Production Operations”, 3

rd

Edition, Elsevier, 2008.

Branan, C., “The Process Engineers Pocket Handbook”, Vol. 2, Gulf, 1983.

Evans, F.L., “Equipment Design Handbook for Refineries and Chemical Plants”, Vol. 2, Gulf,

1974.

Gas Processors Suppliers Association, GPSA Engineering Data Book, 11

th

Edition, Vol. 1, Gas

Processors Association, 1998.

Gerunda, A., “How to Size Liquid-Vapor Separators”, Chemical Engineering, May 4, 1981, 81-84.

Hooper, W.B., “Decantation”, Section 1.11 in “Handbook of Separation Techniques for Chemical

Engineers”, Ph.A. Schweitzer (Ed.), 3

rd

Edition, McGraw-Hill, 1997.

Lyons, W.C., Plisga, G.J. (Editors), “Standard Handbook of Petroleum and Natural Gas

Engineering”, Volume 2, Gulf Professional Publishing, 2005.

Monnery, W.D., Svrcek, W.Y., “Analytical Study of Liquid/Vapor Separation Efficiency”, PTAC,

2000.

Monnery, W.D., Svrcek, W.Y., “Successfully Specify Three-Phase Separators”, Chem. Eng.

Progress, September, 1994, 29-40.

Pourahmadi Laleh, A., "CFD Simulation of Multiphase Separators", PhD Thesis, University of

Calgary, Calgary, Canada, 2010.

Pourahmadi Laleh, A., Svrcek, W.Y., Monnery, W.D., "CFD Simulation of Oilfield Separators: A

Realistic Approach", LAMBERT Academic Publishing, 2011.

Sinnott, R.K., “Chemical Engineering Design” in “Coulson & Richardson’s Chemical

Engineering”, 2

nd

Edition, Butterworth-Heinemann, 1997.

Smith, H.V., “Oil and Gas Separators”, in “Petroleum Engineering Handbook”, Bradley, H.B. (Ed),

Society of Petroleum Engineers, 1987.

Stokes, G.G., “On the Theories of Internal Friction of Fluids in Motion, and of the Equilibrium

and Motion of Elastic Solids”, Transaction of the Cambridge Philosophical Society, 8(22), 1845,

287-305.

Svrcek, W.Y. and W.D. Monnery, "Design Two-Phase Separators within the Right Limits", Chem.

Eng. Prog. 89(10), 53-60, 1993.

Walas, S.M., “Process Vessels”, Chapter 18 in “Chemical Process Equipment Selection and

Design”, Butterworth-Heinemann, 1990.

Watkins, R.N., “Sizing Separators and Accumulators”, Hydrocarbon Proc., 46(11), 1967.

Wu, F.H., “Separators, Liquid-Vapor, Drum Design”, in “Encyclopedia of Chemical Processing

and Design”, J.J. McKetta, W.A. Cunningham (Ed.), Marcel Dekker, 1990.

Separator Sizing

Here we review important guidelines and procedures for

sizing multiphase separators:

General Guidelines

Droplet Settling Theory

Liquid Retention Time

Sizing Procedure

Improvements Offered by CFD Simulations

General Guidelines

Orientation

For

practical

design

of

separators,

it

is

necessary

to

compare

both

horizontal

and

vertical

orientation

designs

to

determine

which

design

is

more

economical

(Svrcek

and

Monnery,

1993).

However,

the

following

general

guidelines

are

recommended

to

be

considered

while

sizing

multiphase

separators.

Vertical orientation

advantages

:

•

Occupy little plot space

•

Easier

than

horizontal

separators

to

transport

and

install

•

Used

when

there

is

small

liquid

load,

limited

plot

space,

or

where

ease

of

level

control

is

desired

(Evans,

1974)

•

Preferred

for

operating

either

low

or

very

high

gas/oil

ratio fluids (Arnold and Stewart, 2008)

Horizontal orientation

advantages

:

•

Higher operating capacity, and processing capabilities

•

Preferred

when

emulsions,

foam,

or

high

gas/oil

ratio

fluids are present (Arnold and Stewart, 2008)

Separator Aspect Ratio (Length/Diameter)

Plot restrictions and economic measures specify the

separator aspect ratio. Different ranges have been suggested

as shown in the table below

Economic

studies

provided

the

separator

aspect

ratio

as

a

function

of

the

operating

pressure

(Walas,

1990;

Svrcek

and

Monnery,

1993).

The

recommended

values

presented

in

the

table

.

The

figures

below

show

illustrated

guidelines

proposed

by

Walas

(1990)

and

Watkins

(1967)

for

two-phase

separators

with and without demisters, respectively.

Design Heuristics Proposed by Walas (1990) for Two-Phase

Separators Equipped with Wire Mesh Demisters.

Design Heuristics Proposed by Watkins (1967) for Two-

Phase Separators.

There

are

also

some

general

guidelines

for

choosing

among

different

horizontal

separators

(see

the

figure

below)

which

are

worth

mentioning:

As

per

Arnold

and

Stewart

(2008),

while

the

simple

design

is

easily

adjustable

to

handle

unexpected

changes

in

liquid

density/flow

rates,

the

bucket

&

weir

design

is

used

when

interface

level

control

is

difficult

(emulsions

or

paraffin

problems).

If

heavy

liquid

mass

fraction

is

substantial,

the

weir

design

is

preferable,

but

the

boot

design

is

preferred

when

heavy

liquid

mass

fraction is less than 20% (Monnery and Svrcek, 1994)

.

(a)

(b)

( c )

(d)

Different Common Designs of Horizontal Three-Phase

Separators; (a) “Simple”, (b) “Boot”, (c) “Weir”, and (d)

“Bucket and Weir”.

Droplet Settling Theory

Liquid Droplet in Vapor Phase

The

force

balance

between

drag

and

gravitational

forces

exerted

on

a

liquid

droplet

leads

to

its

terminal

settling

velocit

y:

Drag

coefficient

for

vapor-liquid

separation

can

be

obtained

from

the

diagram

proposed

by

GPSA.

This

diagram

is

applicable

if

Re

p

is

between

0.4

and

1500.

The

diagram

curve

can

be

regressed

as

shown

in

the

following

with

SI

units

(Monnery and Svrcek, 2000)

:

As

presented

in

the

table,

there

are

different

values

recommended

by

the

field

researchers

for

the

design

droplet

size

.

In

separator

sizing

literature,

it

is

very

common

to

rearrange

the

settling

velocity

equation

introducing

a

K

coefficient,

known

as

the

settling

velocity

coefficient.

This

leads

to

the

Sauders-Brown equation

:

Different

values

are

suggested

in

the

literature

to

be

used

for

the

settling

velocity

coefficient.

The

following

table

provides some of these suggestions

:

More

sophisticated

approaches

recommend

that

pressure

functionality

need

be

considered

for

the

settling

velocity

coefficient.

The

approaches

proposed

by

York

Mist

Eliminator

Company

and

GPSA

are

given

at

below

(Svrcek

and Monnery, 1993):

York Mist Eliminator Compan

y

GPS

A

Liquid Droplet in Liquid Phase

Similar

to

vapor-liquid

separation,

the

force

balance

between

drag

and

gravitational

forces

exerted

on

a

liquid

droplet leads to its terminal velocity

:

It

is

generally

assumed

that

Re

p

is

lower

than

0.1

and

Stokes’

law can be used for calculating the drag coefficient:

C

D

= 24/Re

p

This

assumption

results

in

a

very

simple

equation

for

the

liquid droplet terminal velocity

:

Some

design

droplet

sizes

recommended

in

the

literature

are

shown in the tabl

e.

Liquid Retention Time

In

order

to

handle

upstream

or

downstream

variations

and

establish

smooth

and

safe

operation

of

downstream

facilities,

an

adequate

liquid

retention

time

need

be

assumed.

This

assumption

may

be

based

on

experience,

scale

model

predictions,

or

field

data.

Liquid

retention

time

is

combined

from

holdup

and

surge

time.

Holdup,

considered

for

smooth

and

safe

operation

of

downstream

facilities,

is

defined

as

the

time

it

takes

to

reduce

the

liquid

level

from

normal

to

low

liquid

level

by

closing

inlet

flow

while

maintaining

a

normal

outlet

flow.

Surge

time,

considered

for

handling

upstream

or

downstream

variations,

is

defined

as

the

time

it

takes

to

increase

the

liquid

level

from

normal

to

high

liquid

level

by

closing

outlet

flow

while

maintaining

a

normal

inlet

flow.

Some

rules-of-

thumb

have

been

suggested

at

literature

which

are

not

in

reasonable agreement with each other as shown in the table

.

In

the

more

pragmatic

approach

presented

by

Svrcek

and

Monnery

in

1993

and

1994,

low

liquid

level

is

first

set

based

on

the

operating

pressure

and

diameter

(typical:

6-12

in).

Then,

holdup

(typical:

2-10

min)

and

surge

times

(typical:

1-5

min)

are

specified

based

on

the

service

and

quality

of

the

personnel

and

instrumentation

(with

impact

factor

of

1.0

–

1.5 altogether).

Sizing Procedure

The

sizing

approach

outlined

here

is

proposed

by

Svrcek

and

Monnery

through

two

internationally

acclaimed

papers

in

1993

and

1994.

It

is

an

algorithmic

method

for

designing

the

most

economical

separator.

Among

the

classic

methods,

the

method

offers

the

most

comprehensive

approach

while

benefiting

from

the

accepted

industrial

design

guidelines.

As

explained

in

the

following,

height

adjustments

are

made

for

sizing

vertical

separators

and

iterative

calculations

are

performed

for

finding

the

most

economical

horizontal

separator.

Sizing Vertical Two-Phase Separat

or

1. Calculate the

terminal settling

velocity of liquid

droplets.

2. Set the vapor

velocity equal to 75%

of the terminal

settling velocity.

3. Calculate the vessel

diameter based on the

vapor volumetric

flow-rate and the

vapor velocity.

4. Obtain low liquid

level height (typical:

6-12 in).

5. Calculate the height

from LLL to NLL

based on the required

holdup time (typical:

2-10 min).

6. Calculate the height

from NLL to HLL based on the surge time (typical: 1-5 min).

7. Calculate the height from HLL to the inlet nozzle

centerline based on the inlet nozzle size which can be

calculated as:

8. Assume the disengagement height (H

D

) to be about 0.5D

(Min: 42 in or 30 in with demister).

9. Calculate the vessel height. If the aspect ratio is not in the

range of 1.5-6.0, increase the diameter (to decrease the aspect

ratio) or increase vapor disengagement height (to increase

the aspect ratio) and fix the problem.

Sizing Horizontal Two-Phase Separato

r

In horizontal arrangement,

cross-sectional area of the

vessel is shared by vapor-liquid

disengagement area and areas

for liquid retention and low

liquid level.

Here is the iterative algorithmic

method for sizing:

1. Calculate the terminal settling velocity of liquid droplets.

Use 0.75U

T

as the settling velocity (25% contingency).

2. Calculate the holdup volume based on the required

holdup time (typical: 2-10 min) and liquid volumetric flow

rate.

3. Calculate the surge volume based on the surge time

(typical: 1-5 min) and liquid volumetric flow rate.

4. Assume an aspect ratio (L/D) based on the operating

pressure and calculate an initial diameter:

5. Obtain LLL (typical: 6-12 in) and calculate A

LLL

.

6. Set H

V

to the larger of 0.2D or 1 ft (no demister), 2 ft (with

demister). Calculate A

V

.

7. Calculate L to accommodate the liquid retention volume:

L = (V

H

+V

S

)/(A

T

-A

V

-A

LLL

)

8. Calculate the minimum length required for vapor-liquid

separation: L

min

= (Q

V

/A

V

)(H

V

/U

T

)

9. If L < 0.8L

min

, increase H

V

and go to step 7. Else if L < L

min

,

set L = L

min

. Else if L > 1.2L

min

, decrease H

V

(if acceptable),

and go to step 7. Else (L > L

min

), L is acceptable.

10. If L/D < 1.5, decrease D and go to step 5. Else if L/D > 6,

increase D and go to step 5.

11. Calculate the approximate vessel weight based on the

thickness and surface area of shell and heads.

12. In order to find the optimum case (the minimum weight),

change the vessel diameter by 6 in increments and repeat the

calculations from step 5 while keeping the aspect ratio in the

range of 1.5 to 6.0.

Sizing Vertical Three-Phase Separato

r

1. Calculate the terminal settling velocity of light liquid

droplets.

2. Set the vapor velocity

equal to 75% of the

terminal settling

velocity.

3. Calculate the vessel

diameter based on the

vapor volumetric flow-

rate and the vapor

velocity.

4. Calculate the

separation velocities of

both liquid phases

through each other.

5. Set the thickness of

liquid phases (HLL =

HHL = 0.3 m as

minimum), and

calculate the separation

times for the liquid

droplets (t

HL

and t

LH

).

6. Calculate the cross-sectional areas of the liquid phases.

Note, A

H

is the same as the vessel cross-sectional area (A

H

=

A), but the area allotted to baffle plate down-comer should

be subtracted from A to obtain A

L

.

7. Calculate the residence time of the light liquid:

t

RL

= H

L

A

L

/Q

LL

. If t

RL

< t

HL

increase the vessel diameter so

that t

RL

= t

HL

.

8. Calculate the residence time of the heavy liquid:

t

RH

= H

H

A

H

/Q

HL

. If t

RH

< t

LH

increase the vessel diameter so

that t

RH

= t

LH

.

9. Calculate the height of light liquid phase above the outlet

(H

R

) based on the required holdup time (typical: 2-10 min)

and liquid flow rate.

10. Calculate the surge height (H

S

) based on the surge time

(typical: 1-5 min) and liquid flow rate.

11. Set liquid level above baffle (H

A

= 0.15 m minimum).

12. Calculate the height from NLL to the inlet nozzle

centerline based on the surge height (H

S

) and the inlet

nozzle size which can be calculated as:

13. Assume the disengagement height (H

D

) to be about 0.5D

(minimum: 24”+0.5d

N

with demister or 36”+0.5d

N

no

demister).

14. Calculate the vessel height. If the aspect ratio is not in

the range of 1.5-6.0, increase the diameter (to decrease the

aspect ratio) or height (to increase the aspect ratio) of the

separator and fix the problem.

Sizing Horizontal Three-Phase Separator

In

order

to

show

the

sizing

strategy,

only

“simple”

horizontal

separator

is

presented

here.

The

other

arrangements,

i.e.

“weir”,

“boot”,

and

“bucket

&

weir”,

follow

the

same

strategy

but

require

further

effort

for

sizing

their compartments.

In horizontal arrangement, cross-sectional area of the vessel

is shared by vapor-liquid

disengagement area and

areas for liquid retention

and low liquid level. Here is

the iterative algorithmic

method for sizing:

1. Calculate the terminal

settling velocity of light

liquid droplets. Use 0.75U

T

as the settling velocity (25% contingency).

2. Calculate the holdup volume based on the required

holdup time (typical: 2-10 min) and liquid volumetric flow

rate.

3. Calculate the surge volume based on the surge time

(typical: 1-5 min) and liquid volumetric flow rate.

4. Assume an aspect ratio (L/D) based on the operating

pressure and calculate an initial diameter:

5. Set the thickness of liquid phases (minimum: HLL = HHL

= 0.3 m), and calculate A

LLL

= A

HL

+A

LL

.

6. Set H

V

to the larger of 0.2D or 1 ft (no demister), 2 ft (with

demister). Calculate A

V

.

7. Calculate L to accommodate the liquid retention volume:

L = (V

H

+V

S

)/(A

T

-A

V

-A

LLL

)

8. Calculate the minimum length required for vapor-liquid

separation: L

min

= (Q

V

/A

V

)(H

V

/U

T

)

9. If L < 0.8L

min

, increase H

V

and go to step 7. Else if L < L

min

,

set L = L

min

. Else if L > 1.2L

min

, decrease H

V

(if acceptable),

and go to step 7. Else (L > L

min

), L is acceptable.

10. Calculate the liquid-liquid separation times:

t

HL

= (D-H

V

-HHL)/U

HL

and t

LH

= HHL/U

LH

11. Calculate the light liquid residence time:

t

RL

= L(A-A

V

-A

HL

)/Q

LL

.

If t

RL

< t

HL

increase L so that t

RL

= t

HL

.

12. Calculate the heavy liquid residence time:

t

RH

= LA

HL

/Q

HL

.

If t

RH

< t

LH

increase L so that t

RH

= t

LH

.

13. If L/D < 1.5, decrease D (if acceptable) and go to step 5.

Else if L/D > 6, increase D and go to step 5.

14. Calculate the approximate vessel weight based on

thickness and surface area of shell and heads.

15. In order to find the optimum case (the minimum weight),

change the vessel diameter by 6” increments, and repeat the

calculations from step 5 while keeping the aspect ratio in the

range of 1.5 to 6.0.

Improvements Offered by CFD Simulations

We

have

recently

developed

Computational

Fluid

Dynamics

(CFD)

based

simulation

of

multiphase

separators.

In

order

to

study

selected

aspects

of

phase

separation,

the

focus

was

placed

on

hydrocarbon-water

systems,

and

the

oilfield

separator

data

ranging

from

light

oil

conditions

to

heavy

oil

conditions

were

used

in

these

multiphase

separator

simulations.

An

efficient

combination

of

two

multiphase

simulation

models

available,

VOF

and

DPM,

with

appropriate

model

assumptions

and

settings

was

used.

Two

independent

sets

of

CFD

simulations,

one

for

vapor-liquid

separation

and

the

other

for

liquid-liquid

separation,

were

performed using simple and efficient grid systems.

When

compared

to

classic

design

strategies,

CFD

simulations

indicated

that

additional

residence

times

are

necessary

for

droplets

to

pass

through

the

interfaces.

The

interface

residence

time

may

be

as

high

as

around

100

s

depending on the fluid properties.

In

the

vapor-liquid

separation

compartment,

the

efficient

droplet

size

and

the

appropriate

extra

vapor

residence

time

(for

droplet

penetration

through

the

interface)

were

estimated

as

a

function

of

the

vapor

density.

It

was

shown

that

for

the

three-phase

separator

case

study,

the

efficient

separation

of

oil

droplets

from

gas

phase

results

in

total

separation of water droplets from the gas phase.

For

the

liquid-liquid

separation

process,

the

upper

limit

of

Stokes’

law

(Re

p

<

0.1)

was

exceeded

in

several

case

studies.

Hence,

Abraham

equation

(Re

p

<

2000)

was

recommended

to

be used instead:

Using

the

Abraham

equation

in

liquid-liquid

separation

calculations,

the

efficient

droplet

size

was

estimated

based

on

continuous

phase

viscosity.

Hence,

for

water

droplets,

a

linear

regression

fit

based

on

the

oil

phase

viscosity

was

developed.

An

oil

droplet

size

of

around

600

micron

can

be

assumed

if

the

Abraham

equation

is

used

for

estimation

of

the

rising

velocity

of

oil

droplets

out

of

the

water

phase.

Furthermore,

it

was

shown

that

the

use

of

Stokes’

law

for

interpretation

of

CFD

results

does

lead

to

a

weak

correlation

between

efficient

droplet

sizes

and

continuous

phase

viscosities.

A

comprehensive

CFD-based

study

on

the

velocity

constraints

caused

by

re-entrainment

in

horizontal

separators

confirmed

that,

as

per

practical

experience,

high

vapor

densities

and

high

oil

viscosities

reduce

the

maximum

safe velocity of the vapor phase.

The

results

of

CFD

simulations,

using

all

the

feasible

horizontal

designs

and

selected

oilfield

conditions,

indicated

that

the

oil

phase

does

not

re-entrain

the

water

droplets,

but

the

oil

droplets

may

be

“re-entrained”

by

the

water

phase

at

a

high

velocity.

It

was

also

elucidated

that

the

geometry

of

water

phase

compartment

in

horizontal

separators

is

a

key

factor

affecting

the

liquid-liquid

re-

entrainment

phenomenon.

The

maximum

safe

cross-

sectional

velocity

of

the

water

phase

was

a

linear

function

of

the oil viscosity.

Finally,

it

was

shown

that

the

algorithmic

design

method

of

Monnery

and

Svrcek

(1994)

can

be

modified

to

use

CFD

simulation

results

to

specify

a

realistic

optimum

separator

design/size.

This

fact

was

elaborated

through

the

mobile/desktop

applications

developed

for

sizing

two-phase

and

three-phase

separators.

Please

click

here

for

more

information.

The

serious

process

engineers

can

download

a

complete

and

colourful

version

of

this

interesting

PhD

thesis

from

here

to

acquire more details on practical sizing formula.

References:

Abraham, F.F., “Functional Dependence of Drag Coefficient

of a Sphere on Reynolds Number”, Physics of Fluids, 13,

1970, 2194-2195.

Arnold, K., Stewart, M., “Surface Production Operations”,

3

rd

Edition, Elsevier, 2008.

Branan, C., “The Process Engineers Pocket Handbook”, Vol.

2, Gulf, 1983.

Evans, F.L., “Equipment Design Handbook for Refineries

and Chemical Plants”, Vol. 2, Gulf, 1974.

Gas Processors Suppliers Association, GPSA Engineering

Data Book, 11

th

Edition, Vol. 1, Gas Processors Association,

1998.

Gerunda, A., “How to Size Liquid-Vapor Separators”,

Chemical Engineering, May 4, 1981, 81-84.

Hooper, W.B., “Decantation”, Section 1.11 in “Handbook of

Separation Techniques for Chemical Engineers”, Ph.A.

Schweitzer (Ed.), 3

rd

Edition, McGraw-Hill, 1997.

Lyons, W.C., Plisga, G.J. (Editors), “Standard Handbook of

Petroleum and Natural Gas Engineering”, Volume 2, Gulf

Professional Publishing, 2005.

Monnery, W.D., Svrcek, W.Y., “Analytical Study of

Liquid/Vapor Separation Efficiency”, PTAC, 2000.

Monnery, W.D., Svrcek, W.Y., “Successfully Specify Three-

Phase Separators”, Chem. Eng. Progress, September, 1994,

29-40.

Pourahmadi Laleh, A., "CFD Simulation of Multiphase

Separators", PhD Thesis, University of Calgary, Calgary,

Canada, 2010.

Pourahmadi Laleh, A., Svrcek, W.Y., Monnery, W.D., "CFD

Simulation of Oilfield Separators: A Realistic Approach",

LAMBERT Academic Publishing, 2011.

Sinnott, R.K., “Chemical Engineering Design” in “Coulson

& Richardson’s Chemical Engineering”, 2

nd

Edition,

Butterworth-Heinemann, 1997.

Smith, H.V., “Oil and Gas Separators”, in “Petroleum

Engineering Handbook”, Bradley, H.B. (Ed), Society of

Petroleum Engineers, 1987.

Stokes, G.G., “On the Theories of Internal Friction of Fluids

in Motion, and of the Equilibrium and Motion of Elastic

Solids”, Transaction of the Cambridge Philosophical

Society, 8(22), 1845, 287-305.

Svrcek, W.Y. and W.D. Monnery, "Design Two-Phase

Separators within the Right Limits", Chem. Eng. Prog.

89(10), 53-60, 1993.

Walas, S.M., “Process Vessels”, Chapter 18 in “Chemical

Process Equipment Selection and Design”, Butterworth-

Heinemann, 1990.

Watkins, R.N., “Sizing Separators and Accumulators”,

Hydrocarbon Proc., 46(11), 1967.

Wu, F.H., “Separators, Liquid-Vapor, Drum Design”, in

“Encyclopedia of Chemical Processing and Design”, J.J.

McKetta, W.A. Cunningham (Ed.), Marcel Dekker, 1990.